- Posts: 1045

- Thank you received: 415

3D Printing

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

3 years 7 months ago #25731

by Brian

Replied by Brian on topic 3D Printing

Here's a wing tip being printed in Light Weight PLA from 3DLabPrint, as a buyer of their designs, I was offered a discount and free postage on two 1Kg spools of their new filament, couldn't resist the offer, the price was less for 2Kg than a certain German company was asking for two 500gram spools. The wing tip is being printed to see if it will be compatible with wing parts made with PLA from a different manufacturer. So far the results look promising, the matt and slightly fuzzy surface of the print is pretty much the same as previously printed parts from other filaments. The test will be whether the parts fit together. Exciting stuff, better go and sit down for a while.

The following user(s) said Thank You: 4Pedalsfly

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

3 years 6 months ago - 3 years 6 months ago #25738

by Brian

Replied by Brian on topic 3D Printing

Over the past few days I've discovered a hidden benefit in 3D printed models, for an assortment of reasons I haven't been able to get on with the Moonglow build, so doing a spot of 3D printing more or less made up for it. Fortunately I've just enough spare time to be able to load up the printer and leave it to weave its magic. The current project is back underway since the new spool of PLA arrived, the wing panels take around six hours to print, this means a visit to the shed first thing in the morning, followed by a second visit just after lunch. Seems almost illegal to be able to produce wing panels by simply pressing the "GO" button. Right now I'm like a little boy at Christmas, I had an email today saying that the balsa I ordered for the Moonglow is coming tomorrow. It would have been delivered sooner if I had checked rather more carefully what materials were needed.

Last edit: 3 years 6 months ago by Brian. Reason: Explanatory text added

The following user(s) said Thank You: 4Pedalsfly, Phil Ford

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

3 years 3 months ago #26019

by Brian

Replied by Brian on topic 3D Printing

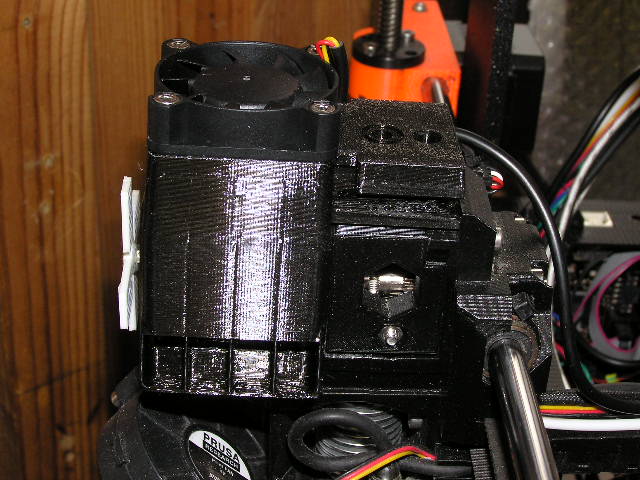

The recent heatwave has brought a whole new bunch of problems. The extruder motor, it sits right above the "Hot Bit" of the extruder, became overheated, what happened was that the filament was softened by the high temperature, instead of sliding neatly down the guide tube, it wrapped itself around the drive gears, and tucked itself into any space it could find. I had to dismantle the extruder in order to clear the jam. This had a "knock on" effect as rebuilding the extruder meant that the Z axis had to be recalibrated. This took a couple of hours, fortunately the printer carried on working after the rebuild, and the current print of a Piper Cub J3 with floats was resumed. I managed to keep the printer working, by putting a fan salvaged from an old power supply, close to the extruder. This kept things working, and no jams happened. I checked the Prusa website for extruder motor cooling mods, and found one! The mod is a cowl that fits over the motor, takes a 40mm fan, and costs less than £20 including postage. Should get the bits before the weekend.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

3 years 3 months ago #26020

by Phil Ford

Replied by Phil Ford on topic 3D Printing

Brian, you could have used an edf to blow over the extruder. :lol: EDFs have other further uses like assisting with getting a charcoal BBQ going quicker. If you had been a Scale Day you would've see a live demonstration.

The following user(s) said Thank You: Brian, MBorrett

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

3 years 3 months ago #26040

by Brian

Replied by Brian on topic 3D Printing

Recently I had the 3DPrintLabs "Joker" up for sale. There wasn't much interest shown and today I removed all the hardware. Good thing that the model didn't sell. While holding the fuselage quite gently as I took out the elevator and rudder servos, the front of the fuselage started to crack. Further squeezing along the fuselage produced more cracks. The material used for the 3D print was a "bargain" from China. The wings and tail, which were printed from a different filament produced in the EU, were as strong as the day they were printed. Fortunately that was the only model I printed "on the cheap". Now its all in the rubbish bin, including the original spool of filament. Could have caused a very unpleasant incident if it had broken up in the air. I've printed a couple of models during my "layoff" from flying, and now before I begin to assemble them, I'm going to print some critical parts and test them for strength.

The following user(s) said Thank You: 4Pedalsfly, Phil Ford

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

3 years 3 months ago #26042

by Brian

Replied by Brian on topic 3D Printing

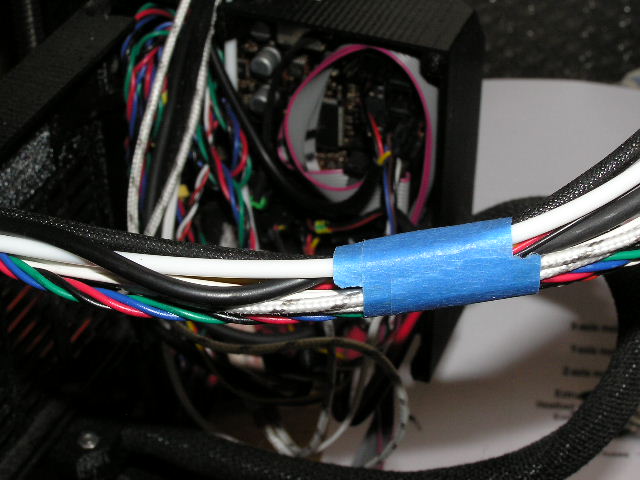

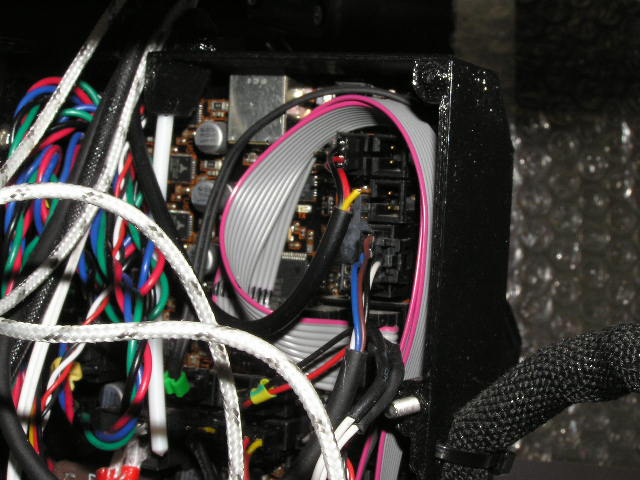

My bits to modify my printer arrived earlier in the week, I'm pleased to report that they were in a smallish padded envelope, not a bit like Colin's monster box. The downloaded (and free) STL files were sliced and copied to the SD card, the printer did its stuff and within a couple of hours I had a shiny new fan shroud ready to fit. It was a couple of days before I could slot in the hours needed to open up the printer's control box and wire in the leads for the new fan. Its a bit disconcerting when the control box door swings open and all the wires make a bid for freedom. Fortunately nothing fell off and nothing broke or got hopelessly entangled in something else. Fortunately the lead for the new fan was the correct length, and with small modification to the connector, plugged in to the main board without any fuss at all. The most awkward job was taming the bunch of assorted wires that connect the extruder head to the control board. I cheated a bit and used some masking tape as a temporary hold until the flexible sleeve could be refitted. The whole job including recalibrating the printer took around five hours. No chocolate biscuits came to any harm during this time, only because I forgot that the Boss had popped them in the fridge during the recent hot spell.

I've done a couple of "push/pull/squeeze/twist tests on a couple of newly printed parts. So far nothing has succumbed to the abuse. I wonder if its an age related fault that affected the Joker's fuselage, that and being in unfriendly environment. In a shed with no insulation, temperatures do tend to be at each end of the scale, and everything is more or less permanently damp. Although the flying surfaces were all OK. I think it must be the poor quality of the filament that caused the failures.

I've done a couple of "push/pull/squeeze/twist tests on a couple of newly printed parts. So far nothing has succumbed to the abuse. I wonder if its an age related fault that affected the Joker's fuselage, that and being in unfriendly environment. In a shed with no insulation, temperatures do tend to be at each end of the scale, and everything is more or less permanently damp. Although the flying surfaces were all OK. I think it must be the poor quality of the filament that caused the failures.

The following user(s) said Thank You: 4Pedalsfly, Phil Ford

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.277 seconds

Latest Posts

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Brian

- 2 weeks 10 hours ago

-

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 3 weeks 2 days ago

-

©

2009 - 2025

WMAC PCF Design