- Posts: 1028

- Thank you received: 583

4-max Motors

- kevinross

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

3 years 2 weeks ago - 3 years 2 weeks ago #26214

by kevinross

4-max Motors was created by kevinross

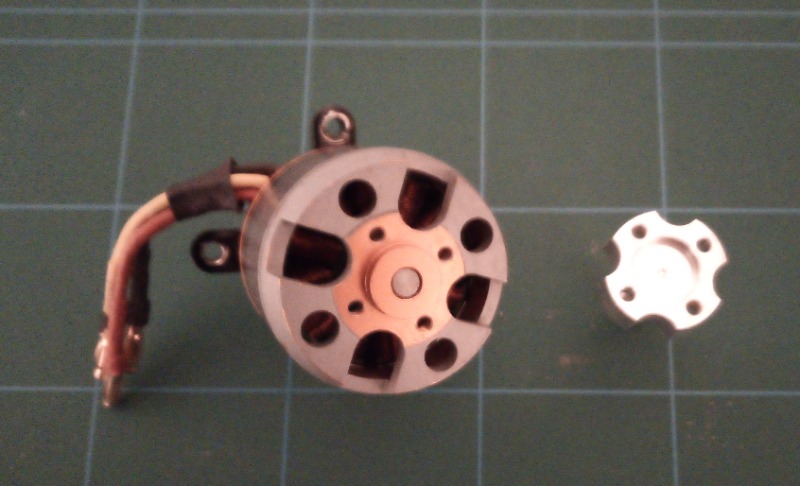

With limited stock in UK shops, I struggled to locate a suitable 50/60 motor with Kv <400 for my latest project so selected a 4-Max 50/65.x 360kv but on receipt I discovered the motor had no register (shoulder) to accurately locate the prop driver. (see pic for an example). Sent a video to 4 -max showing an eccentricity of nearly 15 thou which to my astoishment they were aware of and offered a suggestion to align the driver which I rejected and advised the motor would be returned for refund. I then ordered my first choice from Hobbyking Global which could be up to 30 days shipping 4-max then advised a new batch of motors would be arriving to address this issue and offered a changeout but i responded that should have been the first response and now too late. He claims his motors are made in the same factory as hacker motors The good news is my H/K motor arrived this morning exactly 14 days from order. From what i can gather these H/K motors are also made in the same factory as Hacker motors.

Last edit: 3 years 2 weeks ago by kevinross.

The following user(s) said Thank You: 4Pedalsfly, Brian

Please Log in or Create an account to join the conversation.

- 4Pedalsfly

-

- Offline

- Platinum Member

-

Less

More

- Posts: 803

- Thank you received: 202

3 years 2 weeks ago #26225

by 4Pedalsfly

Replied by 4Pedalsfly on topic 4-max Motors

Interesting posting Kevin, it got me thinking about the brushless motors I've used

over the years.

Most mounted behind the nose cone using the tapped holes in the motor body

and a taper lock prop drive onto the motor shaft, others as per your example.

The photos below are of an unbranded 5055 - 720KV motor rated at 765 W with a 6mm dia shaft

which I used in a now deceased model driving a 14 x 7 prop.

The motor body has a shoulder to locate the prop driver which is retained by 4 hex socket hd capscrews.

Much to my surprise there is a significant clearance between shoulder & prop drive counterbore.

With the 4 screws very lightly tightened it was possible to move the prop drive from side to side.

Without a Dial Gauge, I improvised with a digital vernier, and would estimate this movement at about 20 thou.

So even with a shoulder, if fit of the prop driver is not tightly controlled the problem is still there, perhaps on

more expensive motors this is not the case.

Any comments welcome.

Thanks

Colin.

over the years.

Most mounted behind the nose cone using the tapped holes in the motor body

and a taper lock prop drive onto the motor shaft, others as per your example.

The photos below are of an unbranded 5055 - 720KV motor rated at 765 W with a 6mm dia shaft

which I used in a now deceased model driving a 14 x 7 prop.

The motor body has a shoulder to locate the prop driver which is retained by 4 hex socket hd capscrews.

Much to my surprise there is a significant clearance between shoulder & prop drive counterbore.

With the 4 screws very lightly tightened it was possible to move the prop drive from side to side.

Without a Dial Gauge, I improvised with a digital vernier, and would estimate this movement at about 20 thou.

So even with a shoulder, if fit of the prop driver is not tightly controlled the problem is still there, perhaps on

more expensive motors this is not the case.

Any comments welcome.

Thanks

Colin.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- Brian

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 414

3 years 2 weeks ago #26226

by Brian

Replied by Brian on topic 4-max Motors

I've always taken for granted that the bits supplied with the motor will fit together properly. If the prop driver has a bit of clearance, I suggest that you get some Loctite Bearing Fix, put a film of it on the mating surfaces and loosely assemble the screws, tightening only after the Loctite has cured. This will ensure a much better chance of concentricity.

Please Log in or Create an account to join the conversation.

- kevinross

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

3 years 2 weeks ago - 3 years 2 weeks ago #26227

by kevinross

Replied by kevinross on topic 4-max Motors

The reason i highlighted this issue is

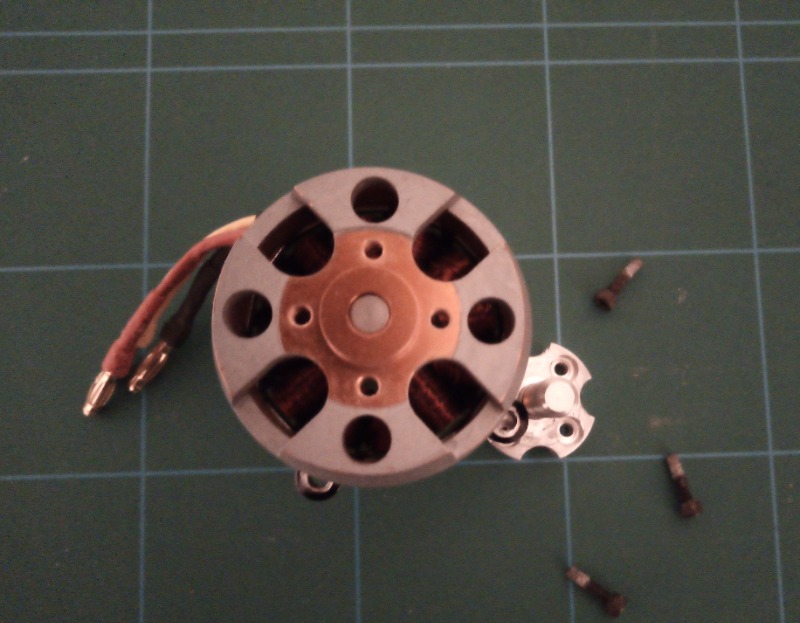

1. My existing 4 -max motor used on the Mic Reeves Gangster runs within 2/3 thou. (see pics )

2. When George Wormley of 4 max gave his talk at the C & Dmfc he went to great lengths to emphasise paying extra attention balancing the prop on E motors - So my complaint to him is thats all negated if the prop driver doesn't run true. !

3. finally i object to being sold a product with a known deficiency

Shame because up to now i've been quite impressed by his knowledge on E flight.

1. My existing 4 -max motor used on the Mic Reeves Gangster runs within 2/3 thou. (see pics )

2. When George Wormley of 4 max gave his talk at the C & Dmfc he went to great lengths to emphasise paying extra attention balancing the prop on E motors - So my complaint to him is thats all negated if the prop driver doesn't run true. !

3. finally i object to being sold a product with a known deficiency

Shame because up to now i've been quite impressed by his knowledge on E flight.

Last edit: 3 years 2 weeks ago by kevinross.

The following user(s) said Thank You: 4Pedalsfly, Phil Ford, Brian

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

3 years 2 weeks ago - 3 years 2 weeks ago #26228

by Phil Ford

Replied by Phil Ford on topic 4-max Motors

And the fact that he knew the prop drivers were less than ideal. So, in theory he was offloading poor manufacturing to those many who would not check the motors, just fit 'em and fly. Of course as the motor size goes up the less then ideal fitment will become more and more apparent and issues will start getting serious.

The two 4-Max motors for my Twotter are 3547 770kv. Prop adaptors are secured by four 2mm screws, they sit "fairly well" on to the motor boss and the screws pull the adaptor down flat. I did notice on both adaptors the drilling on one hole was maybe a 10 thou out.

The two 4-Max motors for my Twotter are 3547 770kv. Prop adaptors are secured by four 2mm screws, they sit "fairly well" on to the motor boss and the screws pull the adaptor down flat. I did notice on both adaptors the drilling on one hole was maybe a 10 thou out.

Last edit: 3 years 2 weeks ago by Phil Ford.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.271 seconds

Latest Posts

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Brian

- 15 hours 13 minutes ago

-

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 2 days ago

-

©

2009 - 2025

WMAC PCF Design