- Posts: 1028

- Thank you received: 583

brushless motor setup / testing

- kevinross

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

3 years 1 day ago #26261

by kevinross

brushless motor setup / testing was created by kevinross

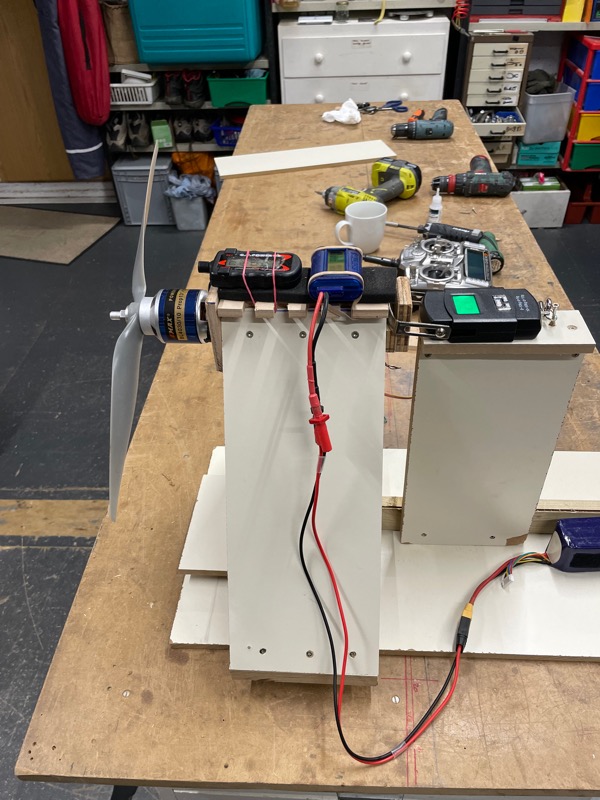

To date all my E models have been been built IAW the manufacturer recommendations but i'm now I'm more involved and establishing my own set ups. I find changing motors on a base model and assembling that model in order to run and test a set up hard work .Last months RCME contained an article on someone's design using heavy duty roller slides which even I thought was a bit OTT. but more importantly i thought debris might eventually jam the slides.

I had some bits and bobs left over from a previous project so cobbled this together to prove the concept. This design used a simpler rocking structure. I can test the electrics, thrust and RPM.

I had some bits and bobs left over from a previous project so cobbled this together to prove the concept. This design used a simpler rocking structure. I can test the electrics, thrust and RPM.

The following user(s) said Thank You: 4Pedalsfly, Brian

Please Log in or Create an account to join the conversation.

- JRI

-

- Offline

- Platinum Member

-

Less

More

- Posts: 504

- Thank you received: 108

3 years 1 day ago #26262

by JRI

Replied by JRI on topic brushless motor setup / testing

What about airspeed measurement (or are you relying on the prop pitch vs rpm)?

If you did have an anenometer in the system you would also be able to measure the propeller efficiency.

If you did have an anenometer in the system you would also be able to measure the propeller efficiency.

Please Log in or Create an account to join the conversation.

- kevinross

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

3 years 37 minutes ago #26264

by kevinross

Replied by kevinross on topic brushless motor setup / testing

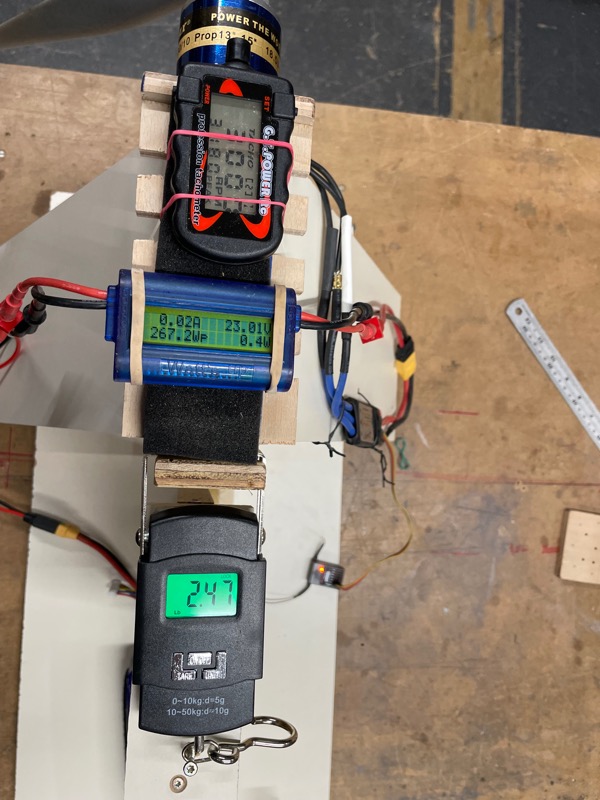

Cant measure airspeed cos its a static test bed !! :woohoo:

I guess knowing the thrust relative to model weight is a good starting point.

I guess knowing the thrust relative to model weight is a good starting point.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3163

- Thank you received: 903

2 years 11 months ago - 2 years 11 months ago #26265

by Phil Ford

Replied by Phil Ford on topic brushless motor setup / testing

Measuring thrust I have done it two ways. With a pusher plane on a smooth surface the nose up against our kitchen scales up against the garage door. Rough guide on thrust. With a normal aircraft on it's wheels, I attached it to my digital luggage scales using a bit of nylon string. Another guide to pulling power. Although just as something to do for info. I try different props and monitor the current drawn so it is all within specs of ESC and motor. I look for a minimum of 100 watts per lb for a warbird although I try to get much more. Civilian may need less. eg: Twin Otter. Each motor (700kv) is pushing at full throttle 600 watts and within the max amps (32a) for the motors. 1200 watts available. Plane weighs 7 1/2 lbs. With the 3 blade 11 x 7 props the Otter is happily flying at less than half throttle therefore extending flight times too.

When flying electric you get to feel it is right or your happy with performance Hence why I have so many props too.:lol: .

When flying electric you get to feel it is right or your happy with performance Hence why I have so many props too.:lol: .

Last edit: 2 years 11 months ago by Phil Ford.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.243 seconds

Latest Posts

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 1 day ago

-

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 2 weeks 22 hours ago

-

©

2009 - 2025

WMAC PCF Design