- Posts: 3163

- Thank you received: 903

Landing Gear Issue

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

9 years 3 weeks ago - 9 years 3 weeks ago #9907

by Phil Ford

Landing Gear Issue was created by Phil Ford

Any Metallurgists? Spent a while removing the main landing gear of the Super Chipmunk on Monday, bending the 8mm wire so that the axles are in line with the wing leading edge. rather than straight down. Two gentle touch downs today and the ruddy things have gone back to the original straight down position.  Which also upsets the wheel spat positions too!

Which also upsets the wheel spat positions too!

Question - Would heating the wire in a certain place to red heat and then rapid cooling help stop this issue or will it make it worse? Or heat up and allow to cool naturally? Or something else?

Question - Would heating the wire in a certain place to red heat and then rapid cooling help stop this issue or will it make it worse? Or heat up and allow to cool naturally? Or something else?

Last edit: 9 years 3 weeks ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- JRI

-

- Offline

- Platinum Member

-

Less

More

- Posts: 504

- Thank you received: 108

9 years 3 weeks ago #9911

by JRI

Replied by JRI on topic Landing Gear Issue

8mm ain't wire - that is serious thickness rod. I am using 6mm approx. (I/2 the strength of 8mm) on my jets and I am finding that stainless steel is the best (I have tried high tensile steel and grade 5 titanium). Piano wire is probably still the best option though but you wont be able to bend it without some serious pressure or a club hammer.

Please Log in or Create an account to join the conversation.

- throttletothewall

-

- Offline

- Senior Member

-

Less

More

- Posts: 171

- Thank you received: 153

9 years 3 weeks ago #9914

by throttletothewall

Replied by throttletothewall on topic Landing Gear Issue

Try this very useful link

vaillyaviation.com/images/Working%20Heat...c%20Wire%20_web_.pdf

by Roy Vaillancourt of Vailly Aviation, where your query is very clearly explained. The only difficulty is when is comes to the tempering as getting the wire evenly heated to 750 C is difficult without doing it in an oven or sandbox.

Hope this helps.

Peter

Hope this helps.

Peter

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3163

- Thank you received: 903

9 years 3 weeks ago - 9 years 3 weeks ago #9915

by Phil Ford

8mm? Sorry John I meant 6mm... :S Needs some effort with the gear locked in a vice to bend it forward. Just surprised yesterday "it" decided to go back to the original position. I had put flats in the axle part for spat securing screws to try and stop the wheel spats swinging loose too.

I am wondering where locally there is a company that could bend stainless wire/rod to my decided shape.

Thanks Peter for the link. In the end I might have a go with the procedure, worth a try. If it don't work then I'll have to get some new legs made up.

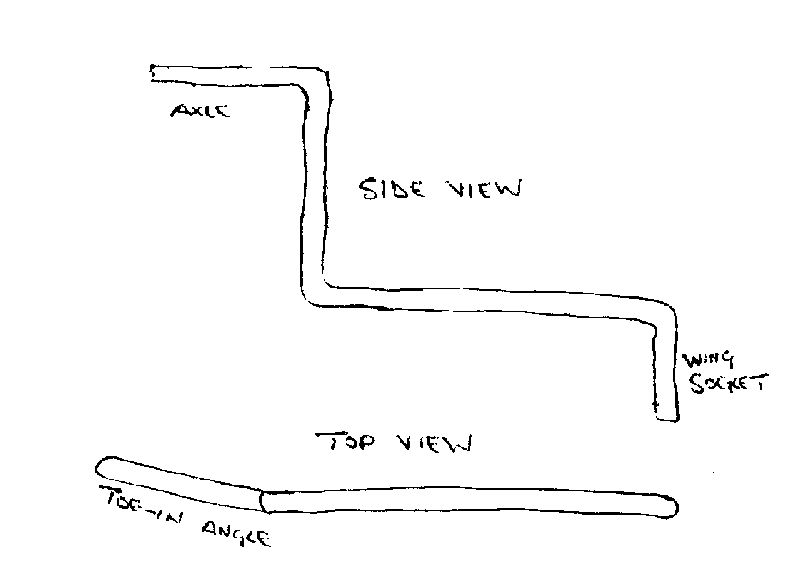

Image shows the port wing gear from the kit.

Replied by Phil Ford on topic Landing Gear Issue

JRI wrote: 8mm ain't wire - that is serious thickness rod.

8mm? Sorry John I meant 6mm... :S Needs some effort with the gear locked in a vice to bend it forward. Just surprised yesterday "it" decided to go back to the original position. I had put flats in the axle part for spat securing screws to try and stop the wheel spats swinging loose too.

I am wondering where locally there is a company that could bend stainless wire/rod to my decided shape.

Thanks Peter for the link. In the end I might have a go with the procedure, worth a try. If it don't work then I'll have to get some new legs made up.

Image shows the port wing gear from the kit.

Last edit: 9 years 3 weeks ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3163

- Thank you received: 903

9 years 3 weeks ago - 9 years 3 weeks ago #9916

by Phil Ford

Replied by Phil Ford on topic Landing Gear Issue

With nothing else better to do I decided to have go with heat treatment. Heated the section requiring bending to a blue heat and the metal allowed me to slowly move it. I then allowed it to cool down naturally. Checking the position when it sits in the wing and adjust as necessary with reheat. Allow to cool again. Reheated to blue going on dull red and immersed into water.

I will leave the spats off for now (looks horrible I know) but want to see if my amateur heat job has done the trick or made it worse... Maybe cut off the main leg leaving a stump to slide on an Oleo leg to absorb landings.

Maybe cut off the main leg leaving a stump to slide on an Oleo leg to absorb landings.

I will leave the spats off for now (looks horrible I know) but want to see if my amateur heat job has done the trick or made it worse...

Last edit: 9 years 3 weeks ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3163

- Thank you received: 903

9 years 2 weeks ago - 9 years 2 weeks ago #9929

by Phil Ford

Replied by Phil Ford on topic Landing Gear Issue

Saturday's rather less than ideal day (crosswinds) and me misjudging the width of our field :oops: I landed a bit awkwardly on the edge. This only slightly bent back one leg a small amount. So, the heat treatment did not make it brittle and snap. Sunday morning to fix it. Got carried away and cut legs off to fit sprung Oleos. These Oleos require 4lbs of pressure each to compress the spring. Will see how the gear fares next time out....

Last edit: 9 years 2 weeks ago by Phil Ford.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.332 seconds

Latest Posts

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 2 days 6 hours ago

-

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 1 week 1 day ago

-

©

2009 - 2025

WMAC PCF Design