- Posts: 3163

- Thank you received: 903

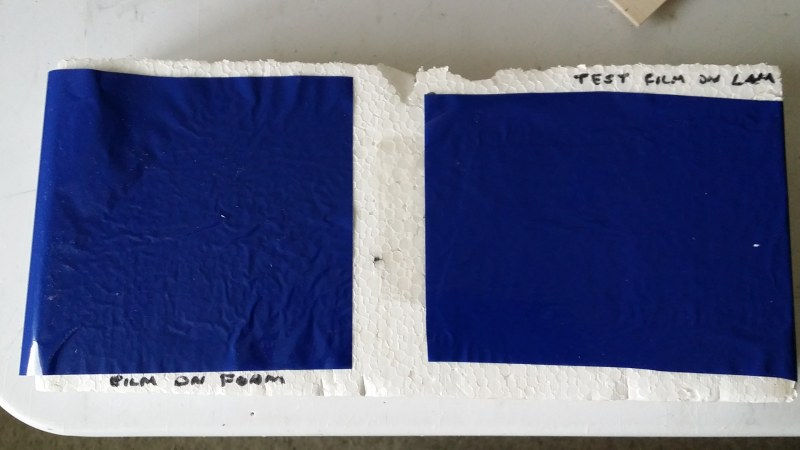

Foam Covering Tests

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

5 years 11 months ago - 5 years 11 months ago #21043

by Phil Ford

Foam Covering Tests was created by Phil Ford

This may be of interest or not but I was. I have not worked with foam much but I have discovered many uses for it other than packaging. Foam is popular today to use in RC for wings and some fuselages. Various types of foams like EPP, EPO, Polystyrene, etc have different characteristics. I am not covering the hard blue foam here. The one thing they don't like is excessive heat. EPP and EPO are usually expanded into a mold, hence our EDFs and more. A bad crash with EPP. EPO can usually be made fairly good by steam or boiling water. However, polystyrene is everywhere and cheap. For a wing we may veneer it with obechi or something similar. But I did not want to go down that path with my recent projects so I got to thinking what else could I use to cover the my foam materials.

I had two problems to solve.

1. An EPP wing covered in GFR Tape (aka Zagi tape). Brilliant stuff and really strengthens flying wings. The coloured packing tape we use sticks fairly well but looks what it is. The Tape on the wing is so well stuck down trying to lift it starts to remove the foiam surface. Best leave well alone then.. But wanted a more resilient coloured covering like Oracover (polyster film) but even after wiping the surface of the tape with Meths to remove any release agent the Oracover would not stick hardly at all.

2. Also had a polystyrene wing that needed stiffening up and was going to use laminating film to cover it. I could spray the laminating film with acrylic car paints or maybe cover with Oracover too?

So, i decided to do some tests on a spare piece of polystyrene foam with results.

1. Test laminating film directly to foam. - - Sticks well

2. Test spray paint to laminating film -- Paints well even with out primer

3. Test Oracover direct to foam -- Sticks but can be lifted a little effort

4. Test Oracover to Laminating film -- Sticks extremely well

5. Test Oracover to GFR Tape -- Sticks but can lifted easily

6. Test Oracover to GFR tape after coating the tape with CoverGrip -- Sticks down very good

I used a covering iron set at 105 deg for the tests except on the last test number 6, where I also went over it at 120 to see if there were problems whilst trying to slightly shrink the film. Not a real issue by the result.

Note: Laminating film is good on flat or square turns but as it does not stretch, compound surfaces and curves have to be a bit of a compromise

So now I know the direction to go with regards to my Custom Wing 1550 and also the Wildthing clone.

I had two problems to solve.

1. An EPP wing covered in GFR Tape (aka Zagi tape). Brilliant stuff and really strengthens flying wings. The coloured packing tape we use sticks fairly well but looks what it is. The Tape on the wing is so well stuck down trying to lift it starts to remove the foiam surface. Best leave well alone then.. But wanted a more resilient coloured covering like Oracover (polyster film) but even after wiping the surface of the tape with Meths to remove any release agent the Oracover would not stick hardly at all.

2. Also had a polystyrene wing that needed stiffening up and was going to use laminating film to cover it. I could spray the laminating film with acrylic car paints or maybe cover with Oracover too?

So, i decided to do some tests on a spare piece of polystyrene foam with results.

1. Test laminating film directly to foam. - - Sticks well

2. Test spray paint to laminating film -- Paints well even with out primer

3. Test Oracover direct to foam -- Sticks but can be lifted a little effort

4. Test Oracover to Laminating film -- Sticks extremely well

5. Test Oracover to GFR Tape -- Sticks but can lifted easily

6. Test Oracover to GFR tape after coating the tape with CoverGrip -- Sticks down very good

I used a covering iron set at 105 deg for the tests except on the last test number 6, where I also went over it at 120 to see if there were problems whilst trying to slightly shrink the film. Not a real issue by the result.

Note: Laminating film is good on flat or square turns but as it does not stretch, compound surfaces and curves have to be a bit of a compromise

So now I know the direction to go with regards to my Custom Wing 1550 and also the Wildthing clone.

Last edit: 5 years 11 months ago by Phil Ford.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- Brian

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1044

- Thank you received: 414

5 years 10 months ago #21153

by Brian

Replied by Brian on topic Foam Covering Tests

How about brown paper and PVA glue Phil? Cheap quick to do and pretty strong. I saw a big EDF Vulcan built this way, foam core brown paper/PVA covering.

Made me wonder if it would be worth trying on a printed model, perhaps lightweight free flight tissue instead of brown paper.

Might try it later, take my mind off the rain and the impending doom called C*******S.

Made me wonder if it would be worth trying on a printed model, perhaps lightweight free flight tissue instead of brown paper.

Might try it later, take my mind off the rain and the impending doom called C*******S.

Please Log in or Create an account to join the conversation.

- DavidTappin

-

- Offline

- Platinum Member

-

Less

More

- Posts: 552

- Thank you received: 164

5 years 10 months ago #21154

by DavidTappin

Replied by DavidTappin on topic Foam Covering Tests

Brian, I’ve been racking my brains to work out what the impending doom that you fear can be and it’s suddenly dawned on me that the C*******S to which you refer is CRASHINGS.

Please Log in or Create an account to join the conversation.

- Brian

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1044

- Thank you received: 414

5 years 10 months ago #21155

by Brian

Replied by Brian on topic Foam Covering Tests

Not quite what I had in mind David, the C*******S I referred to is a terrifying event involving such horrors as mince pies, holly and jolly chaps with white beards(not me) dressed in red suits and going HO HO HO all the time. (They're on work experience and minimum wage so I can't see that the merriment being genuine)

However, all is not doom and gloom, the silly season doesn't last forever, but it does drag on a bit. I saw my first C*******S advert in early July, it was for artificial C*******S trees.

"Apt" I thought. "Very apt"

However, all is not doom and gloom, the silly season doesn't last forever, but it does drag on a bit. I saw my first C*******S advert in early July, it was for artificial C*******S trees.

"Apt" I thought. "Very apt"

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3163

- Thank you received: 903

5 years 10 months ago - 5 years 10 months ago #21156

by Phil Ford

Replied by Phil Ford on topic Foam Covering Tests

Thanks Brian but you are a fair bit behind on this project.  The wing has flown and it is covered in black Profilm ironed on to Deluxe Covergrip. Although another problem for me has reared it's head and is explained in my Tuesday Roll Call post -

wimbornemac.org/forum/roll-calls/2322-tu...-19th-november#21152

The wing has flown and it is covered in black Profilm ironed on to Deluxe Covergrip. Although another problem for me has reared it's head and is explained in my Tuesday Roll Call post -

wimbornemac.org/forum/roll-calls/2322-tu...-19th-november#21152

Last edit: 5 years 10 months ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- JonTappin

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1179

- Thank you received: 265

5 years 10 months ago #21160

by JonTappin

Hi Brian

9 times World F3a champion Christophe Paysant Le Roux, used to cover his contest model wings with brown paper in his earlier days, pretty sure he was still doing it in his first world contests. So you'd be in good company

Replied by JonTappin on topic Foam Covering Tests

Brian wrote: How about brown paper and PVA glue Phil? Cheap quick to do and pretty strong. I saw a big EDF Vulcan built this way, foam core brown paper/PVA covering.

Hi Brian

9 times World F3a champion Christophe Paysant Le Roux, used to cover his contest model wings with brown paper in his earlier days, pretty sure he was still doing it in his first world contests. So you'd be in good company

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.794 seconds

Latest Posts

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 1 day ago

-

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 2 weeks 7 hours ago

-

©

2009 - 2025

WMAC PCF Design