- Posts: 3156

- Thank you received: 903

Back to Basics

- Phil Ford

-

- Offline

- Moderator

-

Please Log in or Create an account to join the conversation.

- MikeSeale

-

- New Member

-

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

- Thank you received: 0

Waving a rolled up newspaper persuaded the wasp that things weren't quite as tranquil as she thought, and it flew out, but stayed around that part of the garden for the best part of an hour before finally giving up and literally buzzing off. The only casualty from the encounter was the neat pile of shavings and balsa dust that I'd roughly scraped together with a view to getting serious with dustpan and brush at the break for lunch, the bits were all over the bench, perhaps I'll have a quick whizz round with the vacuum cleaner before tea.

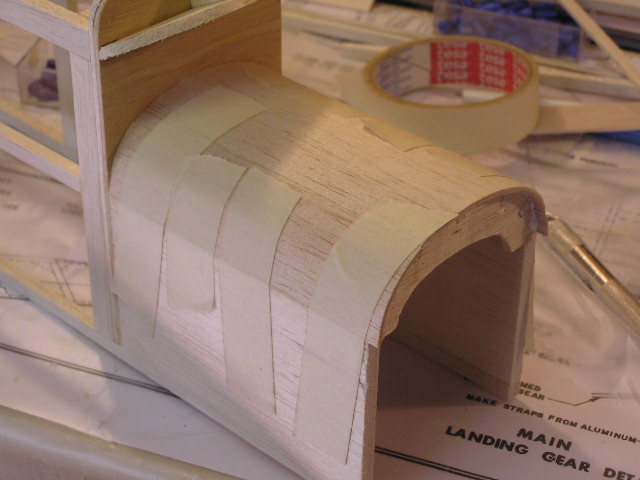

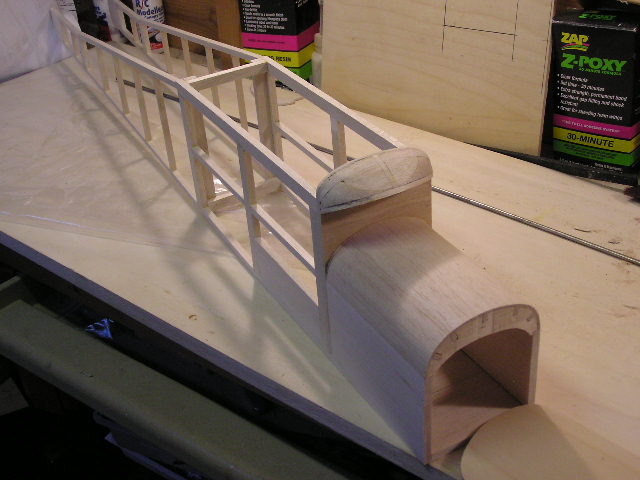

The fuselage sides have now been introduced to the two main formers which are made from 1/4" X 1/2" hard balsa.The original Kadet had a 3/32" ply front former, I didn't have anything that size so I laminated a piece of hard 1/16" sheet and 1mm ply, cut and sanded the laminated former, and glued it to the front face of the front main former. With the formers in place, I was able to glue the front 1/4" balsa sheet sides for the fuselage front end/tank bay. Once again, I should have sat down with the drawing and revamped the structure to make it easier to build, as it is I'm having to draw up parts that would have been printed sheet when the model was first introduced. The first job for tomorrow will be to cut and shape the firewall, then I'll have to decide what to use to power the model. SIG recommend a .19 to .40 two stroke, my original thoughts were electric, but subsequent rummaging didn't turn up a motor that would be powerful enough, but it did unearth an OS FS.52 fourstroke that somehow avoided being sold off during last year's monster clear-out. I do have an Irvine .46(NIB) but I think that wouldn't be in the spirit of the Kadet, which was designed as a slow and gentle flying trainer for three channels, the drawing for adding ailerons looks like an afterthought, and I'm not sure whether to build those, or modify the wing as the more modern ARTF Kadet Senior. Anyway, I'll concentrate on the fuselage for the time being.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

- Thank you received: 0

Note *. When making wide sheets for wing skinning etc. I tidy up the sheet edges to give as near an invisible joint as possible, tape the sheets together, invert them, then slide the assembled sheets to the edge of the bench so that the first part is flat on the bench and the rest of the taped sheets hang straight down. Apply a thin film of your favourite PVA or Aliphatic glue to the joint, then slide the first sheet back along the bench and do the same on subsequent joints. I "squeegee" the joints with an old bank card to get excess glue from the sheet surface. Most times the sheets need no further attention, sometimes they need a bit of inviting to stay flat, in which case use a sheet of polythene and something flat to weigh the sheets down while the glue dries.

Please Log in or Create an account to join the conversation.

- 4Pedalsfly

-

- Offline

- Platinum Member

-

- Posts: 800

- Thank you received: 202

glue to dry and then taking the iron to them is a new one on me.

I.C or Electric ? that O.S four stroke would sound good.

Colin.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

- Thank you received: 0

When ironing on the previous two coverings which are porous until doped, to prevent the iron from becoming all "gooey", I place a strip of woven teflon baking sheet along the edge to be ironed, this also works well if laminating very thin balsa sheet which tends to let the glue migrate.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

- Thank you received: 0

I looked on the SIG USA website to see if I could get some info on the Kadet. The model I'm currently building isn't available, but the Kadet lives in various sizes in kit form or ARTF. The redesigned Kadet is now the Kadet Senior, and is a bit bigger.I was interested to see that the power requirements are quite modest, so My original thoughts of using an OS FS .52 made me realise that the model would be overpowered. I have an OS FS .30 that I think might be a better choice, and being less powerful, perhaps I can get away with a three channel set-up. The original Kadet was three channel, and although I have the official plan for the aileron conversion, it does look very much like an afterthought.

Please Log in or Create an account to join the conversation.

- Chris73

-

- New Member

-

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- JonTappin

-

- Offline

- Platinum Member

-

- Posts: 1178

- Thank you received: 265

Please Log in or Create an account to join the conversation.

- kevinross

-

- Offline

- Platinum Member

-

- Posts: 1023

- Thank you received: 583

Brian wrote: My original thoughts of using an OS FS .52 made me realise that the model would be overpowered. I have an OS FS .30 that I think might be a better choice, and being less powerful, perhaps I can get away with a three channel set-up. The original Kadet was three channel, and although I have the official plan for the aileron conversion, it does look very much like an afterthought.

According to SIG info your FS 30 is below the recommended min power. your 52 is mid range.

re - 2-Stroke .29 - .40 cu. in. (4.8 - 6.5 cc), 4-Stroke .35 - .65 cu. in. (5.7 - 7.4 cc)

Please Log in or Create an account to join the conversation.