- Posts: 847

- Thank you received: 102

Angel dust

- flyingpete

-

- Offline

- Banned

-

Less

More

10 years 1 month ago - 10 years 1 month ago #5321

by flyingpete

Replied by flyingpete on topic Angel dust

Mike,your workshop is far too tidy :ohmy:

Last edit: 10 years 1 month ago by flyingpete. Reason: text

Please Log in or Create an account to join the conversation.

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

10 years 1 month ago #5323

by MikeSeale

15 minutes before that photo was taken it was not so tidy. And here's a pic looking the other way today.

As for the build...not a lot to show but I cut templates and then a foam wing. Tomorrow it's mounting the retracts and servos into the wing, and suitable tunnels for their servo leads before skinning.

Replied by MikeSeale on topic Angel dust

flyingpete wrote: Mike,your workshop is far too tidy :ohmy:

15 minutes before that photo was taken it was not so tidy. And here's a pic looking the other way today.

As for the build...not a lot to show but I cut templates and then a foam wing. Tomorrow it's mounting the retracts and servos into the wing, and suitable tunnels for their servo leads before skinning.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3163

- Thank you received: 903

10 years 1 month ago #5327

by Phil Ford

I was going to mention that too Pete! And space under the worktop, WOW!

Replied by Phil Ford on topic Angel dust

flyingpete wrote: Mike,your workshop is far too tidy :ohmy:

I was going to mention that too Pete! And space under the worktop, WOW!

Please Log in or Create an account to join the conversation.

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

10 years 1 month ago #5339

by MikeSeale

Replied by MikeSeale on topic Angel dust

Four skins...

...two left and two right, ready for sanding

...two left and two right, ready for sanding

Please Log in or Create an account to join the conversation.

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

10 years 1 month ago #5340

by MikeSeale

Replied by MikeSeale on topic Angel dust

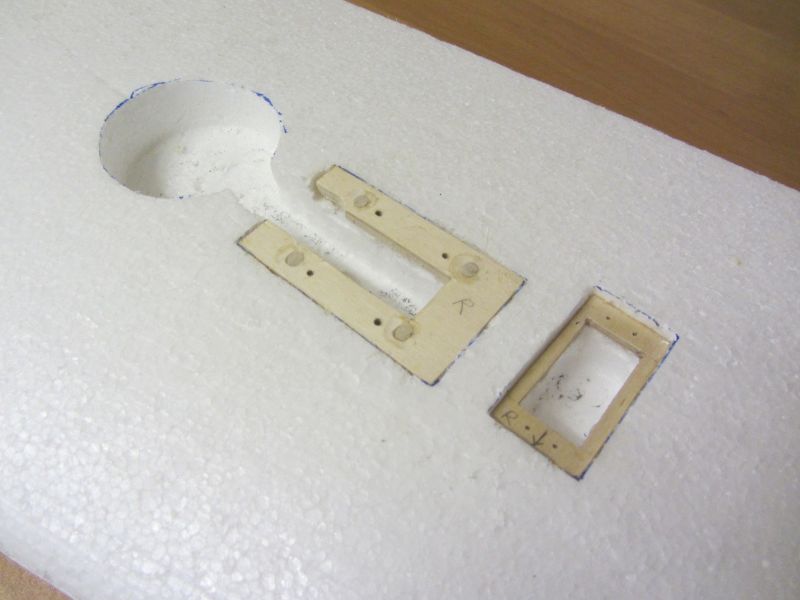

Most of the work today was on the foam cores. Cutouts were made for the retracts and aileron servos. After cutting the sides with a sharp scalpel I used a sanding drum on my dremel to cut into the foam. Dremel in one hand and the workshop vac in the other...saves a lot of mess.

The mounting plate for the retracts has 4 dowels epoxied into the foam. These are angled like a saw-horse and will hopefully spread the load on those heavy landings.

I also cut channels for the servo leads. I decided to make them big enough to take the large connector on the end of an extension lead so I can easily swap servos and retracts if necessary.

Tomorrow it's wing skinning time and fin construction...

The mounting plate for the retracts has 4 dowels epoxied into the foam. These are angled like a saw-horse and will hopefully spread the load on those heavy landings.

I also cut channels for the servo leads. I decided to make them big enough to take the large connector on the end of an extension lead so I can easily swap servos and retracts if necessary.

Tomorrow it's wing skinning time and fin construction...

Please Log in or Create an account to join the conversation.

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

10 years 1 month ago #5351

by MikeSeale

Replied by MikeSeale on topic Angel dust

First job of the day was to lightly sand the wing skins...much easier to sand before you glue them to a curved wing. Then it was time to glue the skins on using Gorilla glue. This is when I spread the glue onto the freshly sanded surface instead of the unsanded side :oops: After spreading the glue the skins are added and the wings are placed back in their offcuts, then taped and weighted down for a few hours while the polyurethane glue foams and dries. Compared to contact adhesive or epoxy, this is a much cleaner and easier glue to work with.

The base of the fin was tack glued in place and rough carved. The fin itself is drying.

The wheel wells are lined and leading and trailing edges are added.

The base of the fin was tack glued in place and rough carved. The fin itself is drying.

The wheel wells are lined and leading and trailing edges are added.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.360 seconds

Latest Posts

-

-

- Pitts Special 120FS

- In WimborneMac Members / For Sale - Exchange - Wanted

- by superadmin

- 1 week 5 days ago

-

©

2009 - 2025

WMAC PCF Design