- Posts: 1179

- Thank you received: 265

Rebuild Thread - EF 104 Extra

- JonTappin

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

9 years 8 months ago #8356

by JonTappin

Replied by JonTappin on topic Rebuild Thread - EF 104 Extra

Thanks for the comments chaps  Haven't managed to get much time on this for the last couple of weeks but hope to get back on it over Easter, will update again when I've got some progress to show

Haven't managed to get much time on this for the last couple of weeks but hope to get back on it over Easter, will update again when I've got some progress to show

Please Log in or Create an account to join the conversation.

- Dante

-

- Offline

- Junior Member

-

Less

More

- Posts: 79

- Thank you received: 7

9 years 8 months ago #8359

by Dante

Replied by Dante on topic Rebuild Thread - EF 104 Extra

Just goes to show that in the 70's and 80's when kits had to be built from scratch or die cut parts at best, before CNC and laser cutting, developed skills honed from experience that seem to be lost in the present day of total ARTF. Congratulations on a really skilled rebuild, skills once learnt will always stay with you. Really well done Jon, look forward to the re-maiden in due course.

The following user(s) said Thank You: JonTappin

Please Log in or Create an account to join the conversation.

- JonTappin

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1179

- Thank you received: 265

9 years 7 months ago - 9 years 7 months ago #8456

by JonTappin

Replied by JonTappin on topic Rebuild Thread - EF 104 Extra

Been back on it this week at last.

Next job was remake the root rib, this is laminated from 2mm ply and balsa, cut out by hand using the bits left over as a pattern, filling in missing bits by taking dimensions from the other wing. Once made I had to make sure the incidence pins and wing tube lined up with the fusleage accurately, I mounted the rib using the aluminium pins, then using the wing tube and a pencil I covered the end with lencil lead and used it to mark the root rib.

Next job was remake the root rib, this is laminated from 2mm ply and balsa, cut out by hand using the bits left over as a pattern, filling in missing bits by taking dimensions from the other wing. Once made I had to make sure the incidence pins and wing tube lined up with the fusleage accurately, I mounted the rib using the aluminium pins, then using the wing tube and a pencil I covered the end with lencil lead and used it to mark the root rib.

Last edit: 9 years 7 months ago by JonTappin.

Please Log in or Create an account to join the conversation.

- JonTappin

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1179

- Thank you received: 265

9 years 7 months ago #8457

by JonTappin

Replied by JonTappin on topic Rebuild Thread - EF 104 Extra

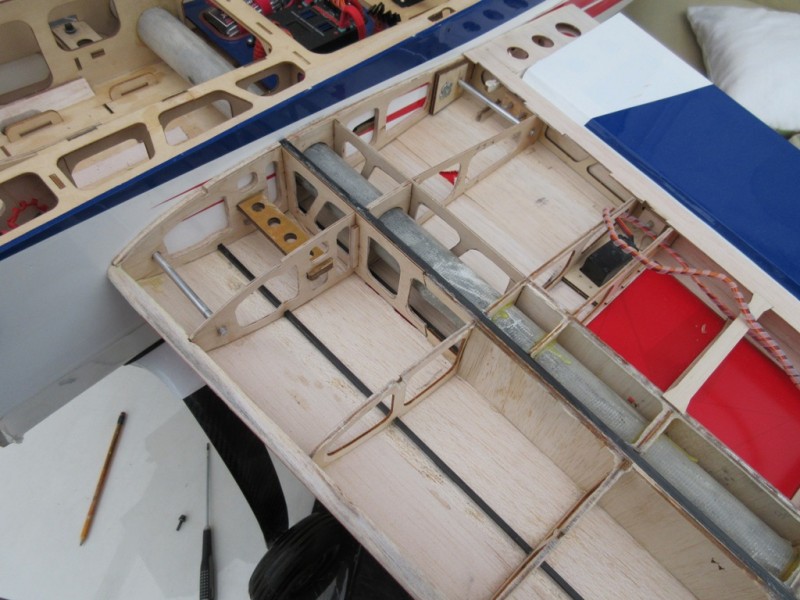

These photos show all of the remade internal parts complete, then assembly into the wing, I managed to copy some of the original location tabs to make sure everything lined up correctly.

I assembled everything dry, then when happy wicked this cyano into the joints.

You will see that there was a reasonable amount of damage to the bottom wing skin from these pictures, this would be dealt with as one of the next jobs!

I assembled everything dry, then when happy wicked this cyano into the joints.

You will see that there was a reasonable amount of damage to the bottom wing skin from these pictures, this would be dealt with as one of the next jobs!

Please Log in or Create an account to join the conversation.

- JonTappin

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1179

- Thank you received: 265

9 years 7 months ago #8458

by JonTappin

Replied by JonTappin on topic Rebuild Thread - EF 104 Extra

Next, the root rib went in, followed by the aluminium incidence pegs and the the balsa spar webbing facing the ply pieces

Please Log in or Create an account to join the conversation.

- JonTappin

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1179

- Thank you received: 265

9 years 7 months ago - 9 years 7 months ago #8460

by JonTappin

Replied by JonTappin on topic Rebuild Thread - EF 104 Extra

Next I tackled the wing tube liner repair. As mentioned earlier in the thread, I was concerned about this as I had to do it with the wing tube in to ensure it kept it's shape, I was right to be concerned as it nearly caught me out.

Using part of the original broken wing tube, I covered it with silicon grease then inserted it into the tube being careful not to snag the broken edges of the liner tube which is made from very thin glass cloth. I then took some wing skinning cloth, cutting small pieces, laying them on then soaking in this CA. While I did this I kept rotating the carbon tube to make sure it didn't bond, I wasn't expecting it to bond with the silicon grease layer, but when I tried to rotate it I couldn't :ohmy: Luckily by turning it as hard as I could it broke free before the glue really had time to properly bond, there was much relief!! Had I not been able to release it, it would have been a disaster

It was really surprising that the glue bonded through the layer of grease, lesson learnt and luckily no harm done.

The repair was successful in the end.

Using part of the original broken wing tube, I covered it with silicon grease then inserted it into the tube being careful not to snag the broken edges of the liner tube which is made from very thin glass cloth. I then took some wing skinning cloth, cutting small pieces, laying them on then soaking in this CA. While I did this I kept rotating the carbon tube to make sure it didn't bond, I wasn't expecting it to bond with the silicon grease layer, but when I tried to rotate it I couldn't :ohmy: Luckily by turning it as hard as I could it broke free before the glue really had time to properly bond, there was much relief!! Had I not been able to release it, it would have been a disaster

It was really surprising that the glue bonded through the layer of grease, lesson learnt and luckily no harm done.

The repair was successful in the end.

Last edit: 9 years 7 months ago by JonTappin.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.418 seconds

Latest Posts

- No posts to display.

©

2009 - 2025

WMAC PCF Design