- Posts: 3170

- Thank you received: 903

Goldberg Super Chipmunk

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

5 years 9 months ago #21668

by Phil Ford

Replied by Phil Ford on topic Goldberg Super Chipmunk

Wing now covered. White and Red. Wanted white and blue but did not have enough blue so it got red. Beginning to like it after all. :lol: Landing gear back on. Got some fiddling to do the align the wing bolts with the fuselage mounting blocks. Tomorrow, wet n windy Sunday, will probably install my custom servo tray and fit the elevator and rudder servos. Will post up some images later. Done enough for today.....she said.

Please Log in or Create an account to join the conversation.

- JonTappin

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1179

- Thank you received: 265

5 years 9 months ago #21669

by JonTappin

Why don't you just use the exhaust that's on it?

Replied by JonTappin on topic Goldberg Super Chipmunk

Phil Ford wrote:

Saito is 12mm x 1 thread apparently.Won't take ASP exhaust me thinks

Why don't you just use the exhaust that's on it?

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

5 years 9 months ago #21672

by Phil Ford

Replied by Phil Ford on topic Goldberg Super Chipmunk

I will use the muffler but may have to extend or angle the it bit more and I have a quite few ASP / OS manifold adaptors

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

5 years 9 months ago #21694

by Phil Ford

Replied by Phil Ford on topic Goldberg Super Chipmunk

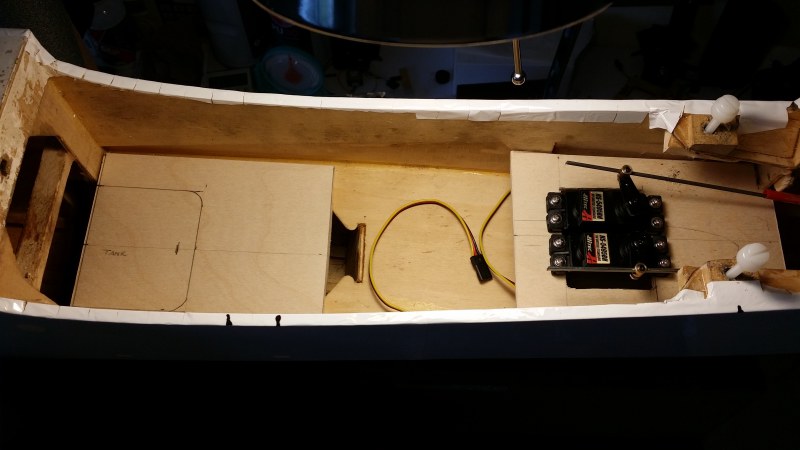

Some progress at last although I have just seen a a bit of a boo boo. When I made up the servo tray for the rudder and elevator servos I had not allowed room for a throttle servo. :oops: Oh well no big deal just have to cut out another one. The Saito 80 is now mounted although I did have some trials though because two of the the engine mounting brackets lined up nicely with a bearer on the inside of the firewall, this being as the builder was fitting a different engine and was also mounted horizontally. I had to bite the bullet on a very expensive (in my estimation) a right angle exhaust adaptor from Saito (thanks Motor & Rotors who had one in stock). At least now the exhaust will point downwards and back out of the cowl. Next job on top the servo tray remake is the tank plate to hold it in place and also for the securing of battery pack/s. My suspicion is that even with the weight of the lump up front the battery may have to go right up front to avoid adding lead ballast to get the CG right.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

5 years 9 months ago - 5 years 9 months ago #21698

by Phil Ford

Replied by Phil Ford on topic Goldberg Super Chipmunk

Two steps forward and one back. Had to move the engine forward 3.5 mm to give enough clearance for spinner without having to jam the cowl hard back against the fuselage which also gives me a bit of leeway when aligning the prop driver to cowl out hole. Simple enough you would think - but no, the spike nuts that took me ages to install fell out. My hands are to big to get into the fuselage tank area and it was struggle last time. One hour of p***ing about trying to them back in, three cups of coffee and a ball-pein hammer nearby. Finally now I can try the cowl again with the right angle adaptor fitted. A bit more cutting needed. To finalise the exhaust may be a bit of trial though. Re-installed tank after boring out a 30mm hole for the lines to come out. Servo tray remade and servos fitted. Until I know what is happening with the exhaust I am unable to paint the cowl or where to fit the securing screws.

I know it was probably 9 years a go but Ebay has got a lot to answer for.

I know it was probably 9 years a go but Ebay has got a lot to answer for.

Last edit: 5 years 9 months ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- Brian

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

5 years 9 months ago #21700

by Brian

Replied by Brian on topic Goldberg Super Chipmunk

I used to get fed up when a spike nut fell off, and it would always be the one you couldn't reach. I replaced all my spike nuts with threaded inserts, they cost a bit more, but they do make engine fitting a breeze.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.420 seconds

Latest Posts

- No posts to display.

©

2009 - 2025

WMAC PCF Design