- Posts: 3170

- Thank you received: 903

What's the best way to proceed

- Phil Ford

-

- Offline

- Administrator

-

Less

More

7 years 11 months ago #15423

by Phil Ford

Replied by Phil Ford on topic What's the best way to proceed

Save weight at same time. My Fox had a solid plastic rod weighing a fair old bit. Measuring it I find that the Angel carbon wing tube fits. So I bought a piece and saved 75% weight. 7mm carbon -

7mm Carbon

Please Log in or Create an account to join the conversation.

- John Bannister

-

- Offline

- Senior Member

-

Less

More

- Posts: 158

- Thank you received: 98

7 years 11 months ago #15424

by John Bannister

Replied by John Bannister on topic What's the best way to proceed

The thing about using silver steel it should be tougher so not bend as easily as mildsteel so could do more damage to wing if it should happen again you wont break either steel or carbon fibre in normal flight I would have thought . Mild Steel should have bent on impact the silver steel and carbon fibre would be likely to break as they are more brittle.

Now your totally confused

Now your totally confused

Please Log in or Create an account to join the conversation.

- 4Pedalsfly

-

- Offline

- Platinum Member

-

Less

More

- Posts: 803

- Thank you received: 202

7 years 11 months ago #15425

by 4Pedalsfly

Replied by 4Pedalsfly on topic What's the best way to proceed

Chris - Wing joiner, I would go for carbon fibre tube.

Worth popping in Hengistbury Kites , located on road leading to Hengistbury Head, they stock various sizes &

if you take the wing in they can find one which is a snug fit.

He has lots of offcuts sold off cheaply.

Colin

Worth popping in Hengistbury Kites , located on road leading to Hengistbury Head, they stock various sizes &

if you take the wing in they can find one which is a snug fit.

He has lots of offcuts sold off cheaply.

Colin

The following user(s) said Thank You:

Please Log in or Create an account to join the conversation.

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

7 years 11 months ago #15434

by

Replied by on topic What's the best way to proceed

Thanks Colin, I'd not thought to seek out a kite shop, but that's really good to know.

I'll grab some steel rod and hopefully get it back to where I left off, then experiment with a carbon wing joiner. Considering the kit came with two lengths of carbon tube that run the full length of the ailerons, and the design isn't that old, they must have chosen a solid steel rod over the alternatives for a reason, it doesn't strike me the extra cost of a carbon tube would have made that much difference to the price. But gliders are very new to me, it seems half the time people want them heavier and the other half want them lighter!

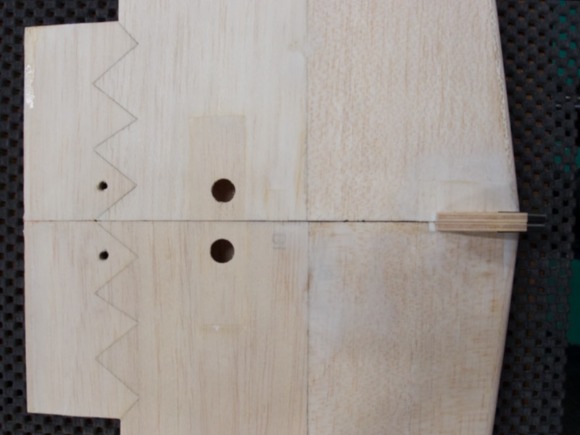

I made a start on two new root ribs this evening.

I'll grab some steel rod and hopefully get it back to where I left off, then experiment with a carbon wing joiner. Considering the kit came with two lengths of carbon tube that run the full length of the ailerons, and the design isn't that old, they must have chosen a solid steel rod over the alternatives for a reason, it doesn't strike me the extra cost of a carbon tube would have made that much difference to the price. But gliders are very new to me, it seems half the time people want them heavier and the other half want them lighter!

I made a start on two new root ribs this evening.

Please Log in or Create an account to join the conversation.

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

7 years 10 months ago #15696

by

Replied by on topic What's the best way to proceed

The pleasure of getting it wrong… so many times

My wing joiner was bent, and so I ordered a 7mm silver steel rod to replace it, on arrival I cut it to length, bevelled the ends and polished it with some polishing paste I had lying around. It looked perfect so I popped it into the wing, and discovered it was a little restrictive, not deterred I kept going, twisting it back and forth while shoving it in. At some point the resistance got beyond a joke and I quickly retreated, after a little bit of wrangling and some very sore fingers I got it out.

My beautifully polished rod was now scored, so I went back and polished it up again, a trial fit of the bent rod into the tube was fine, so I figured I must have caught a little bit of swarf on my last attempt so I proceeded without caution, it felt a little smoother and then all of a sudden it locked up. I could maybe budge it 5º this way and that but no more, I wiggled it back and forth whilst the rod was clamping in a vice, it was slow progress and after fifteen minutes I decided to put a tape marker against the edge so I could see how much progress I was actually making extracting the rod, five minutes later the tape had not budged even a fraction of a mm.

I considered my options, but it basically came down to one, twist the wing beyond the 5º of play and see what happens, I figured I would either break the wing, the rod would come free, or I would extract the rod with the glued in aluminium tube. There was a reassuringly frightening crack and out came the rod with the tube.

To free the rod from the tube I drilled a 7mm hole in a piece of MDF, which took the rod but stopped at the 8mm diameter tube, with a slimmer bit of steel rod down the tube I hammered it out, progress was good and both rod and tube punched their way through the MDF without parting company! I repeated the process with a hole in a lump of beach and thankfully that did the trick.

Googling to find 8mm aluminium tubing with a 0.5 wall thickness was not encouraging, so I thought I’d have to try and fix the original tubing, this involved lots of attempts to polish the inside, by putting the steel rod in a drill, liberally dousing the inside of the tube with polishing paste, and with the drill running I slid on the tube, in hindsight this might have ended in injury, but luckily not on this occasion. You could not ask for a better fit, it was really smooth. So I cleaned it all up did a trial fit and managed to lock the two together again, this happened several times, what was in Einstein said about repeating the same thing and expecting a different outcome?

Fortunately I alighted upon some 8mm tube with a 0.45mm wall thickness, and eagerly anticipated the delivery. The rod fitted the tube perfectly, all that was left was to cut it to length pop it back into the wing and I would be well on my way to repairing the wing.

It was when dry fitting the new tube that I discovered I’m a slow learner. It appears the new tube was reluctant to slide in where the old tube had been, and I was again stuck with a bit of metal well and truly jammed and sticking out of the wing! Eventually I managed to extract it and decided to see if I could free up the holes through the ribs by putting the spare bit of tube, with sharpened end, in a hand drill and whilst spinning the tube I was able to feel my way through, success! In with the pre-cut length and it jammed again, my sense of humour for this project was bordering on failing at this point. After some barbaric practices I was able to extract the tube and I decided to cut my losses. I went back to the off-cut which was over length and putting it back in the drill. I spun the tube into place with copious amounts of CA, and then cut it flush… Done!

The balsa wood repairs went okay, so it's just a little tidying up to do and I think I'm ready to recover the wing.

Any thoughts on using 4mm carbon tube for the pins that secure the leading edge into the fuselage?

My wing joiner was bent, and so I ordered a 7mm silver steel rod to replace it, on arrival I cut it to length, bevelled the ends and polished it with some polishing paste I had lying around. It looked perfect so I popped it into the wing, and discovered it was a little restrictive, not deterred I kept going, twisting it back and forth while shoving it in. At some point the resistance got beyond a joke and I quickly retreated, after a little bit of wrangling and some very sore fingers I got it out.

My beautifully polished rod was now scored, so I went back and polished it up again, a trial fit of the bent rod into the tube was fine, so I figured I must have caught a little bit of swarf on my last attempt so I proceeded without caution, it felt a little smoother and then all of a sudden it locked up. I could maybe budge it 5º this way and that but no more, I wiggled it back and forth whilst the rod was clamping in a vice, it was slow progress and after fifteen minutes I decided to put a tape marker against the edge so I could see how much progress I was actually making extracting the rod, five minutes later the tape had not budged even a fraction of a mm.

I considered my options, but it basically came down to one, twist the wing beyond the 5º of play and see what happens, I figured I would either break the wing, the rod would come free, or I would extract the rod with the glued in aluminium tube. There was a reassuringly frightening crack and out came the rod with the tube.

To free the rod from the tube I drilled a 7mm hole in a piece of MDF, which took the rod but stopped at the 8mm diameter tube, with a slimmer bit of steel rod down the tube I hammered it out, progress was good and both rod and tube punched their way through the MDF without parting company! I repeated the process with a hole in a lump of beach and thankfully that did the trick.

Googling to find 8mm aluminium tubing with a 0.5 wall thickness was not encouraging, so I thought I’d have to try and fix the original tubing, this involved lots of attempts to polish the inside, by putting the steel rod in a drill, liberally dousing the inside of the tube with polishing paste, and with the drill running I slid on the tube, in hindsight this might have ended in injury, but luckily not on this occasion. You could not ask for a better fit, it was really smooth. So I cleaned it all up did a trial fit and managed to lock the two together again, this happened several times, what was in Einstein said about repeating the same thing and expecting a different outcome?

Fortunately I alighted upon some 8mm tube with a 0.45mm wall thickness, and eagerly anticipated the delivery. The rod fitted the tube perfectly, all that was left was to cut it to length pop it back into the wing and I would be well on my way to repairing the wing.

It was when dry fitting the new tube that I discovered I’m a slow learner. It appears the new tube was reluctant to slide in where the old tube had been, and I was again stuck with a bit of metal well and truly jammed and sticking out of the wing! Eventually I managed to extract it and decided to see if I could free up the holes through the ribs by putting the spare bit of tube, with sharpened end, in a hand drill and whilst spinning the tube I was able to feel my way through, success! In with the pre-cut length and it jammed again, my sense of humour for this project was bordering on failing at this point. After some barbaric practices I was able to extract the tube and I decided to cut my losses. I went back to the off-cut which was over length and putting it back in the drill. I spun the tube into place with copious amounts of CA, and then cut it flush… Done!

The balsa wood repairs went okay, so it's just a little tidying up to do and I think I'm ready to recover the wing.

Any thoughts on using 4mm carbon tube for the pins that secure the leading edge into the fuselage?

Please Log in or Create an account to join the conversation.

- kevinross

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

7 years 10 months ago - 7 years 10 months ago #15698

by kevinross

Replied by kevinross on topic What's the best way to proceed

Chris

To clear an interference in the wing tube you could produce a "D-Bit" on the end of your silver steel to ream out any imperfections using a battery drill on slow speed.

Cut away the material with a hacksaw then grind away to just past the centre . If you have access to a water or oil bath grinder you will produce perfect sharp cutter and a very usable reamer.

remove on a regular basis and clean out the swarfe. Adding a little grease will help.

To clear an interference in the wing tube you could produce a "D-Bit" on the end of your silver steel to ream out any imperfections using a battery drill on slow speed.

Cut away the material with a hacksaw then grind away to just past the centre . If you have access to a water or oil bath grinder you will produce perfect sharp cutter and a very usable reamer.

remove on a regular basis and clean out the swarfe. Adding a little grease will help.

Last edit: 7 years 10 months ago by kevinross.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.269 seconds

Latest Posts

- No posts to display.

©

2009 - 2025

WMAC PCF Design