- Posts: 886

- Thank you received: 129

3D Printing

- DaveBright

-

- Offline

- Moderator

-

Less

More

25 Aug 2019 14:25 #20622

by DaveBright

Replied by DaveBright on topic 3D Printing

Looking good Brian! Clever stuff. How long does it take to print something? Presumably an ‘over night’ job?

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

25 Aug 2019 16:01 #20624

by Brian

Replied by Brian on topic 3D Printing

3D printing is very much a "press a button and go find something else to do." The article showing two parts of the new flying wing's centre section, finally turned out at thirteen hours forty something minutes. That was my fault, the printing speed can be adjusted over a wide range. When starting a print, the layers are thin (0.013mm) and the extruder is hot at 230 degrees C, the bed is hot too, 60 degrees C. The centre section took a long while because I'd omitted to increase the printing speed after the initial layers had been established. At the moment, another wing section is printing, the projected time is 7 hours 37 minutes. I'm not bothering to make any samples for testing, this one's going to fly........I hope!

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

25 Aug 2019 16:12 #20625

by Brian

Replied by Brian on topic 3D Printing

I think it might be interesting to print a prop Phil, there's quite a choice of diameters and pitches. I haven't looked at the prop program, but from the names of the files it seems that it a hub-and-blade arrangement. To be honest, I don't know if I'll ever be able to design something that can be printed. I've been struggling with the P-47 design. I can get an image of the parts into "3-D" mode, but so far I haven't been able to make any alterations to the joint areas. The flying wing by Eclipson has a much stronger joining arrangement, with lots of surface area for the glue to hang on to.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

26 Aug 2019 07:48 #20631

by Brian

Replied by Brian on topic 3D Printing

Recently I bought an upgrade kit for the printer, part of the kit contents was a reel of black PET-G. I used the leftovers to print the props and hubs.

The assembled propeller will be 10" X 4.7" CCW. There is a spinner for the hub, I didn't find the data for it until I'd started the print. There are three or four props of differing diameters and pitches in the program. I'll print some of each type when I print the spinner

The assembled propeller will be 10" X 4.7" CCW. There is a spinner for the hub, I didn't find the data for it until I'd started the print. There are three or four props of differing diameters and pitches in the program. I'll print some of each type when I print the spinner

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

26 Aug 2019 16:40 - 26 Aug 2019 16:45 #20633

by Brian

Replied by Brian on topic 3D Printing

The prop blades needed to have their leading edges tidied up, apart from that, A gentle sanding with 400 grit paper around the leading and trailing edges was all that was needed. The blades and hub have all the mounting holes printed in. The blades fitted snugly into the hub with no additional work at all. The blades are held in with M2.5 screws, The screws are a clearance fit in the blade and one arm of the hub. The other arm has an undersize hole which is perfect to allow the retaining screw to be screwed in. The design showed its American origin at this stage, the width over the hub's arms is 1/2" exactly. The motor is an Overlander 1100kV. My only criticism of the hub's design is that both arms have the "tapped" hole for the retaining screw on the same side. The fact that the screw heads are on the same side of the hub centre line will probably cause vibration. In any case I shall keep well away from the side of the model when running the motor.Perhaps I'll alter the arrangement and use studding and nuts instead of screws.

Last edit: 26 Aug 2019 16:45 by Brian.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

27 Aug 2019 15:05 #20637

by Brian

Replied by Brian on topic 3D Printing

I was feeling quite pleased with myself, I'd transferred a couple more wing sections to be printed, and I hadn't referred to the prompt sheet. Good job I checked the print before it got too far. I had completely forgotten to alter the "infill" box from the default 15% to the new one, which is zero. As you can see from the photo, there's a lot of material doing nothing much but adding needless weight and stiffness to the section. I should have twigged it when the print time for these two sections was greater than the previous ones, which were a lot larger. Still, not to worry, all part of the learning curve.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

29 Aug 2019 17:45 - 29 Aug 2019 17:47 #20650

by Brian

Replied by Brian on topic 3D Printing

My printer is a Prusa i3 Mk3, its about two years old, and a year or so ago, he model was upgraded from Mk3 to Mk3S. Prusa made a kit of parts available to existing Mk3 owners who wanted the extra versatility. Handy if you want to make 3D model aeroplanes. When my kit arrived, it consisted of all the hardware needed and a 300g spool of black PET-G filament. Having bought the kit, this unlocks the download from Prusa that enables the printer to print the parts needed for the upgrade.Pretty neat, a machine that makes its own new parts.

Photo ...904.JPG is the extruder, photo...905 is the upgraded parts. This all seemed easy, almost too easy to be true. It was! The parts in the photo might look OK, but in fact they were flawed. I found that the cause was the way that the filament had been wound on to the spool, it had a couple of places where the faulty winding had effectively trapped the filament on its way to the extruder. This meant that the printer kept printing, totally oblivious of the fact that it wasn't getting sufficient filament to do the job properly. Funny thing, the upgrade is, apart from any other features, to prevent the printer from running without the filament being correctly extruded. I took photos of the faulty spool and sent them to Prusa. In less than a week I received a completely new kit accompanied by a thank you note from their tech department. Most encouraging. When I've finished printing the present project, I'll get on with the upgraded again.

Photo ...904.JPG is the extruder, photo...905 is the upgraded parts. This all seemed easy, almost too easy to be true. It was! The parts in the photo might look OK, but in fact they were flawed. I found that the cause was the way that the filament had been wound on to the spool, it had a couple of places where the faulty winding had effectively trapped the filament on its way to the extruder. This meant that the printer kept printing, totally oblivious of the fact that it wasn't getting sufficient filament to do the job properly. Funny thing, the upgrade is, apart from any other features, to prevent the printer from running without the filament being correctly extruded. I took photos of the faulty spool and sent them to Prusa. In less than a week I received a completely new kit accompanied by a thank you note from their tech department. Most encouraging. When I've finished printing the present project, I'll get on with the upgraded again.

Last edit: 29 Aug 2019 17:47 by Brian.

Please Log in or Create an account to join the conversation.

- Decks5712

-

- New Member

-

Less

More

- Thank you received: 0

30 Aug 2019 06:55 #20651

by Decks5712

Replied by Decks5712 on topic 3D Printing

Looking good Brian.

Like yourself I printed all the upgrades for my printer, but now`s the time to upgrade my printer. so I will be selling my Ender 3 Pro with various filliments and bits and bobs as I am now joining the Resin printer collective. Just have a couple of more jobs to complete before I`ll let her go.

Like yourself I printed all the upgrades for my printer, but now`s the time to upgrade my printer. so I will be selling my Ender 3 Pro with various filliments and bits and bobs as I am now joining the Resin printer collective. Just have a couple of more jobs to complete before I`ll let her go.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

30 Aug 2019 07:49 - 30 Aug 2019 07:53 #20652

by Brian

Replied by Brian on topic 3D Printing

That sounds interesting Alan, is the resin suitable for 3D printed R/C aeroplanes? I remember seeing a printer being demonstrated by Raymond Baxter on a BBC programme called "Tomorrow's World", that one used a UV laser and a UV cured resin. It was really crude when compared to the printers we can get now.

Last edit: 30 Aug 2019 07:53 by Brian.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

30 Aug 2019 08:28 #20654

by Brian

Replied by Brian on topic 3D Printing

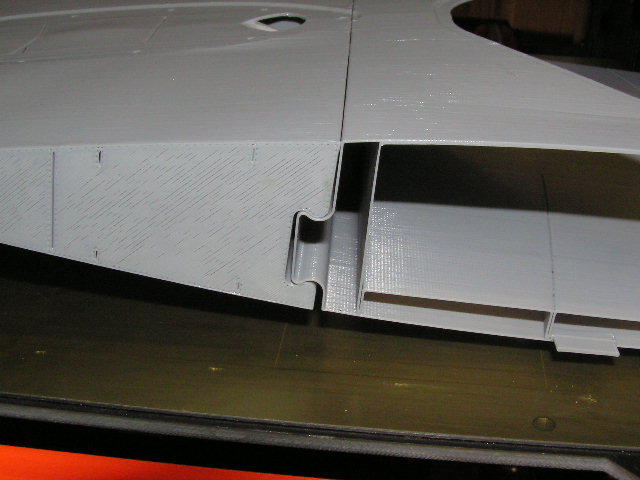

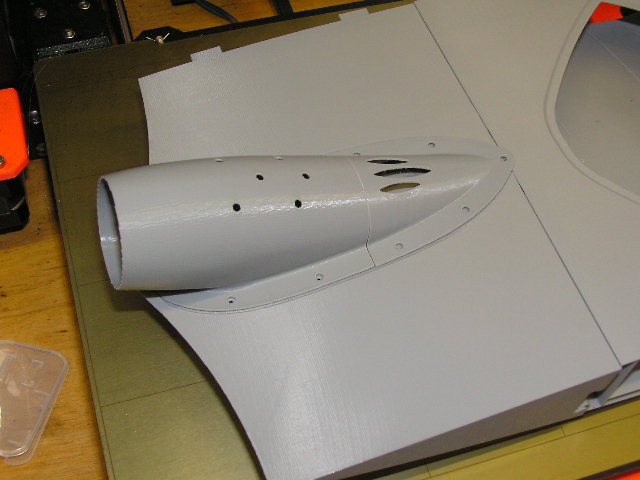

Considering the advances that have been made in computer aided design and manufacturing, I shouldn't keep being surprised when things fit together perfectly, joined by either glue or screws that go into holes that weren't made with a drill. The next few items of the Eclipson Blackwing will be assembled with a mix of glue and screws. I still think its pretty neat that the parts are usable straight off the printer. Seventy years ago I was a young aero-engineering apprentice, drilling and tapping the six holes in the motor mount and motor housing would have been a long and probably not particularly accurate process. Sometimes I feel a little guilty when I see how easy it is to make stuff that works first time every time, but its comforting to know that a part is being printed, even when I'm elsewhere, dutifully pushing SWMBO's goodie filled trolley to the car park

The photos are of the motor mount/ housing assembly, the "dovetail" spanwise joint between front and rear centre section, the recess in the top surface for the motor housing, note the moulded in hole for the motor wires. and finally the motor housing perched in place.

The photos are of the motor mount/ housing assembly, the "dovetail" spanwise joint between front and rear centre section, the recess in the top surface for the motor housing, note the moulded in hole for the motor wires. and finally the motor housing perched in place.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.396 seconds

Latest Posts

-

-

- Valkyrie Slope Soarer

- In Activities / Glider & Slope

- by Phil Ford

- 22 Feb 2026 13:03

-

©

2009 - 2026

WMAC PCF Design