- Posts: 552

- Thank you received: 164

BVM Mig.15

- DavidTappin

-

- Offline

- Platinum Member

-

Less

More

8 years 5 months ago #11600

by DavidTappin

Replied by DavidTappin on topic BVM Mig.15

Pete, so sorry to hear your sad news, I've PM'd you

Please Log in or Create an account to join the conversation.

- flyingpete

-

- Offline

- Banned

-

Less

More

- Posts: 847

- Thank you received: 102

8 years 5 months ago #11620

by flyingpete

Replied by flyingpete on topic BVM Mig.15

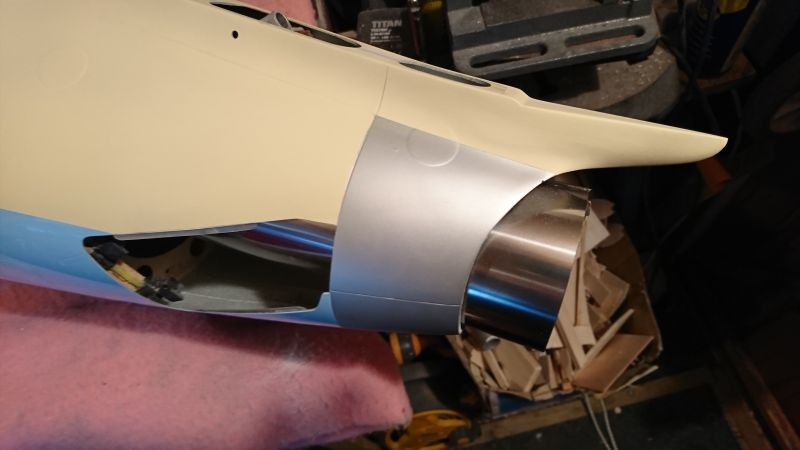

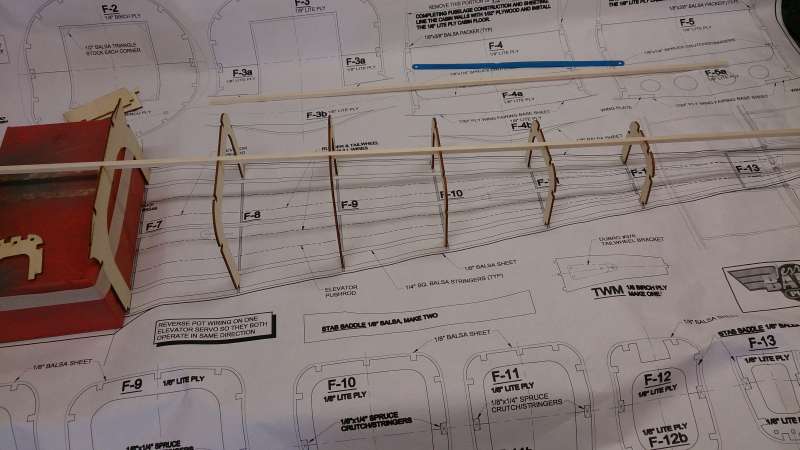

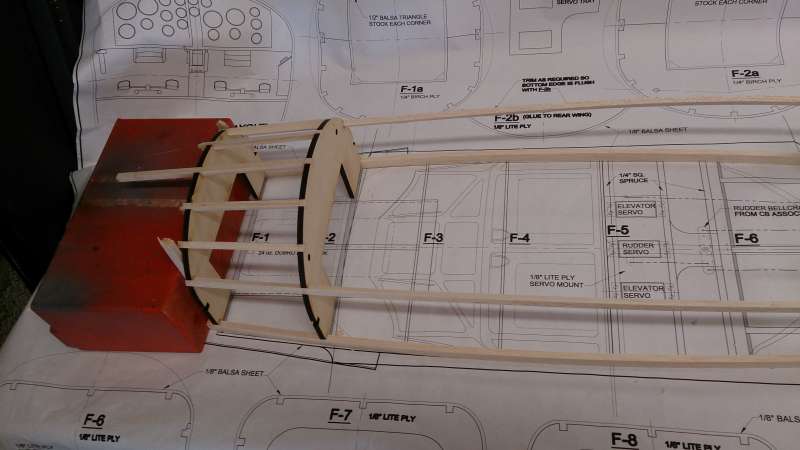

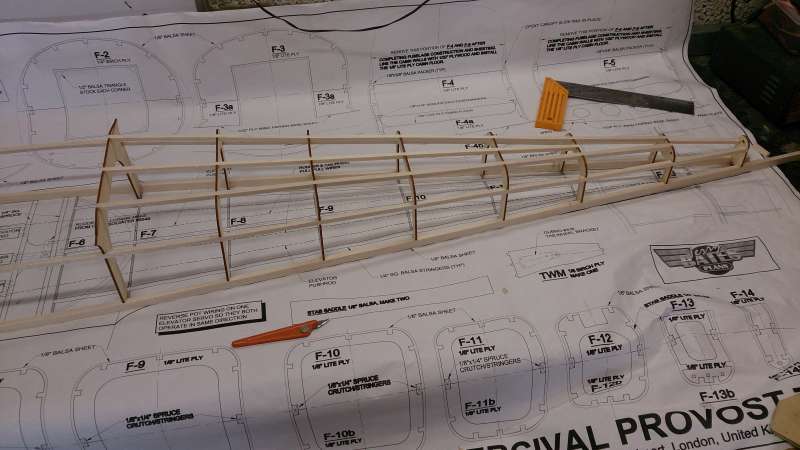

Some pictures of the fitting of the tailpipe from last weekend. First job was to cut the tailpipe to the shape of the rear fuzz and fit the strengthening ring. Four maple blocks glued in, to hold the pipe in position.

Please Log in or Create an account to join the conversation.

- flyingpete

-

- Offline

- Banned

-

Less

More

- Posts: 847

- Thank you received: 102

8 years 5 months ago #11621

by flyingpete

Replied by flyingpete on topic BVM Mig.15

Few more

Please Log in or Create an account to join the conversation.

- JonTappin

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1179

- Thank you received: 265

8 years 5 months ago #11623

by JonTappin

Replied by JonTappin on topic BVM Mig.15

Very tidy!

Please Log in or Create an account to join the conversation.

- flyingpete

-

- Offline

- Banned

-

Less

More

- Posts: 847

- Thank you received: 102

8 years 5 months ago #11624

by flyingpete

Replied by flyingpete on topic BVM Mig.15

To protect the speed brake servos from heat I have wrapped another ceramic blanket around the tailpipe in their location. To secure I have used carbon tow wraps soaked in thin can.

Please Log in or Create an account to join the conversation.

- flyingpete

-

- Offline

- Banned

-

Less

More

- Posts: 847

- Thank you received: 102

8 years 5 months ago - 8 years 5 months ago #11625

by flyingpete

Replied by flyingpete on topic BVM Mig.15

Inner and outer tailpipe's fitted together, note the inner pipe is set back 25mm from the outer pipe as per the BVM instructions. On the turbine end, I have set inner pipe back 30mm from the cone as per the norm. This measurement is quite critical as too close to the turbine tail cone and it will suffocate the turbine and restrict power. If its too far away you run the risk of not collecting all the heat and flames from the turbine and in nanno seconds the model will be a fire ball.

In the last pick you can see the heat blanket through the speed brake aperture.

I will show details of the turbine installation when I get back on the mig over the weekend.

.

In the last pick you can see the heat blanket through the speed brake aperture.

I will show details of the turbine installation when I get back on the mig over the weekend.

.

Last edit: 8 years 5 months ago by flyingpete.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.669 seconds

Latest Posts

-

-

- Turbine Suspension

- In Activities / Jet Flight and EDF

- by JonTappin

- 1 week 5 days ago

-

-

-

- Volantex Observer FPV or Camera Carrier

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 2 weeks 3 days ago

-

©

2009 - 2025

WMAC PCF Design