- Posts: 1048

- Thank you received: 415

Back to Basics

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

2 years 1 month ago #25710

by Brian

Replied by Brian on topic Back to Basics

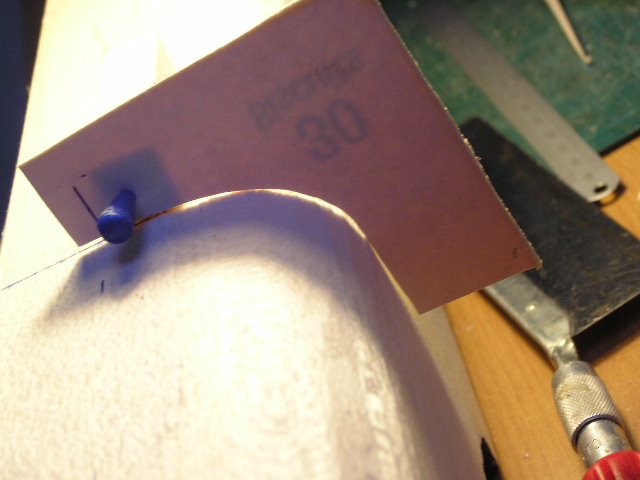

The second stage planing brings the shape close to the required profile. The plane blade has been re-sharpened and is set to cut a finer shaving at this stage. The photo shows the gap between template and fuselage, the light emphasises the gap which is about 1mm in places.

The following user(s) said Thank You: kevinross, Phil Ford

Please Log in or Create an account to join the conversation.

- 4Pedalsfly

-

- Offline

- Platinum Member

-

Less

More

- Posts: 810

- Thank you received: 208

2 years 1 month ago #25711

by 4Pedalsfly

Replied by 4Pedalsfly on topic Back to Basics

Brian - Progressing well,

reference to " Deac" on plan certainly dates the design.

Pleased to see you are now allowed indoors to bash balsa.

Regards

Colin

reference to " Deac" on plan certainly dates the design.

Pleased to see you are now allowed indoors to bash balsa.

Regards

Colin

Please Log in or Create an account to join the conversation.

- kevinross

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 558

2 years 1 month ago #25712

by kevinross

Often wondered why they had the name DEAC, apparently its Deutsche Edison-Akkumulatoren-Company GMBH

Replied by kevinross on topic Back to Basics

Brian - Progressing well,

reference to " Deac" on plan certainly dates the design.

Pleased to see you are now allowed indoors to bash balsa.

Regards

Colin

Often wondered why they had the name DEAC, apparently its Deutsche Edison-Akkumulatoren-Company GMBH

The following user(s) said Thank You: 4Pedalsfly

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1048

- Thank you received: 415

2 years 1 month ago #25713

by Brian

Replied by Brian on topic Back to Basics

Colin, I'm permitted to use the spare room only on condition that I "don't make a mess". The build is taking a bit longer due to the hourly whizz round with the hand held vac, and the proximity of the biscuit tin. Apart from a slight ridge here and there, the fuselage is ready for the first sanding. I had to assemble the bits to see what it looked like.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1048

- Thank you received: 415

1 year 11 months ago - 1 year 11 months ago #25795

by Brian

Replied by Brian on topic Back to Basics

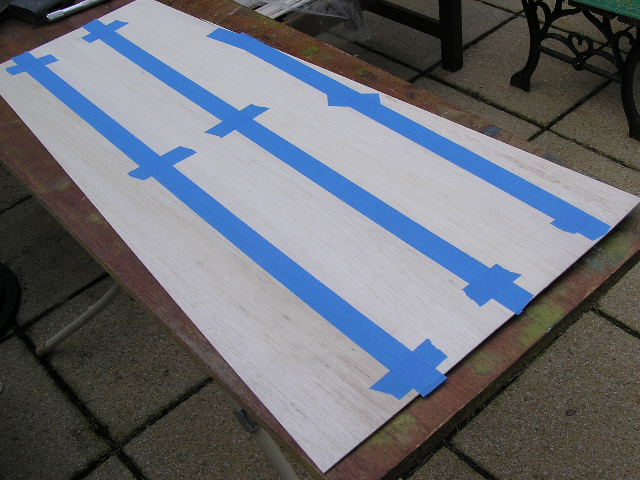

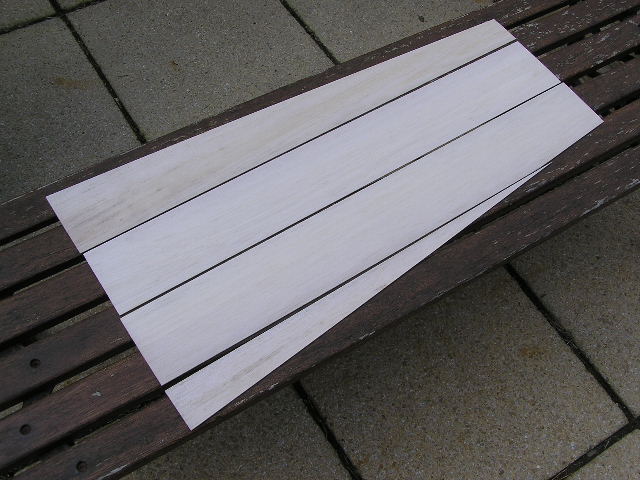

I didn't realise how long it has been since I did a bit more work on Moonglow, that's the trouble with having fun! Today I've started to make the 1/16" sheet panels for the wing skins. I cut the wing plan from the main drawing, this saved a lot of time messing about with pencil, ruler, square etc. also minimised the risk of getting it wrong, something I do quite often these days. Fortunately the balsa sheet was straight, and the edges needed no cleaning up before gluing. I've tacked on a couple of pictures as there might be a few who've never seen the way a large sheet of balsa is made. Two things help the job go smoothly. First, always use fresh masking tape, this ensure the tape won't let go before the glue dries, second, use a fine tipped glue applicator, its all too easy to squirt too much glue into the joint with messy consequences. I got mine from a craft shop, think it might have been HobbyCraft, not sure. With the sheets firmly taped, the whole thing is flipped over and held on to the building board by one panel. This gives an open "vee" joint which helps guide the tip of the applicator quite nicely. The panel is then slid across the building board, closing the newly glued joint and opening the second one. I scraped off any excess glue with an old credit card before wiping the joint over with a piece of kitchen paper. Finally, the joints are covered with polythene film and weighted down. I made the panels as "handed pairs", this will give matched surfaces for both wings.

Last edit: 1 year 11 months ago by Phil Ford.

The following user(s) said Thank You: kevinross

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1048

- Thank you received: 415

1 year 11 months ago - 1 year 11 months ago #25797

by Brian

Replied by Brian on topic Back to Basics

Made a start on building Moonglow's right wing this afternoon. The plan is a bit vague about the structure and hinging of the ailerons, I'll have to work out a way which will ensure that they don't warp when they are cut away from the main structure. I have the original build article written by Mike Birch, and that is lacking in places. I'm going to try to use the method that Peter Miller favours for building sheeted wings, that is to remove the wing structure from the building board, invert it, then pin and glue the structure to the sheet, working from the TE towards the LE. This will enable the fragile 3/8" X 1/8" TE section to be supported by the sheet. At the moment the plan shows the TE butted to the trailing edges of the ribs, and with the structure being "up in the air" so to speak, getting it accurately placed and fixed isn't really practical. With the top skin fixed to the structure, this should allow me to add a leading edge to the aileron. This will be built clear of the rear spar using a 1/32" spacer, also a new "riblet" will be needed to close the inboard end of the aileron, once again spaced 1/32" from the wing rib. After the aileron structure and hinge points are made, it'll be possible to mark the position of the aileron on to the wing skin, making it easier to cut away from the main structure. I'll take a few pictures of the build as I go, should help make sense of the above description.

Last edit: 1 year 11 months ago by Brian. Reason: Added extra information to help clarify the procedure.

The following user(s) said Thank You: 4Pedalsfly, kevinross

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.448 seconds

Latest Posts

-

-

- Fixed wing FPV pilots?

- In Activities / Jet Flight and EDF

- by kevinross

- 2 days 14 hours ago

-

-

-

- How old are your Fuel Lines?

- In Activities / Gas-n-Glow

- by Phil Ford

- 3 days 16 hours ago

-

-

-

- F4 Scale World championships 2024

- In Main Forum / Announcements

- by DavidTappin

- 5 days 16 hours ago

-

-

-

- Back to Basics

- In Activities / Kits n Scratch Build

- by kevinross

- 1 week 2 days ago

-

-

-

- Valkyrie Slope Soarer

- In Activities / Glider & Slope

- by Phil Ford

- 1 week 5 days ago

-

-

-

- RC Model World Sportstar

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Brian

- 2 weeks 1 day ago

-

©

2009 - 2024

WMAC PCF Design