- Posts: 3170

- Thank you received: 903

Morris Dancer build

- Phil Ford

-

- Offline

- Administrator

-

Less

More

8 months 2 weeks ago - 8 months 2 weeks ago #26924

by Phil Ford

Replied by Phil Ford on topic Morris Dancer build

Today I have covered all the tail parts in orange except for the fin and rudder. I ran out of orange so I decided to cover the rudder in bright yellow like the fuselage.

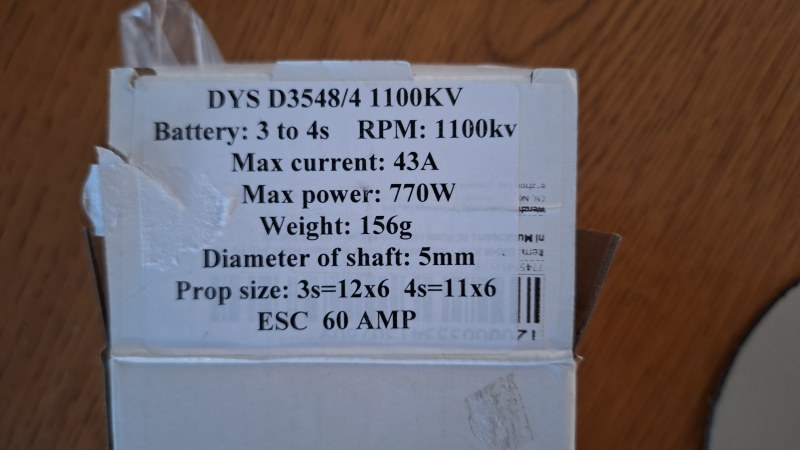

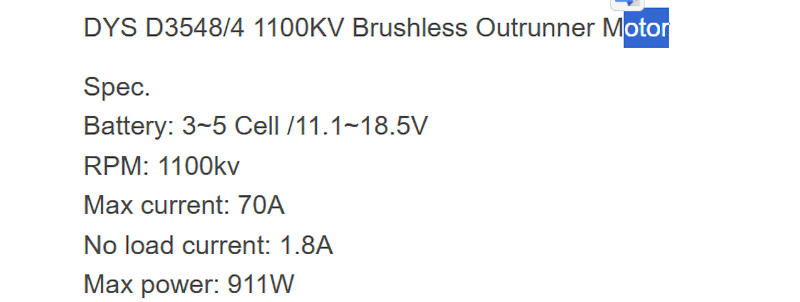

Another motor arrived today too as per Chris's post earlier. Bolts straight on. Gave it a quick test with a 12x8 APC. Ran it on 4 cells. WOT for a few seconds. 52 amps. That exceeds the motor spec. The box it came in says 3 - 4 cells, 43 amps 770 watts. The sellers website says otherwise. On 5 cells, 11x7 maybe around 900 watts.

Will play around with cells and props to see what I get. Although I think anything in 200 watts per lb is adequate to muck about with at Cashmoor.

I will start hinging the bits this week (waiting on 2mm screws to secure horns).

Another motor arrived today too as per Chris's post earlier. Bolts straight on. Gave it a quick test with a 12x8 APC. Ran it on 4 cells. WOT for a few seconds. 52 amps. That exceeds the motor spec. The box it came in says 3 - 4 cells, 43 amps 770 watts. The sellers website says otherwise. On 5 cells, 11x7 maybe around 900 watts.

Will play around with cells and props to see what I get. Although I think anything in 200 watts per lb is adequate to muck about with at Cashmoor.

I will start hinging the bits this week (waiting on 2mm screws to secure horns).

Last edit: 8 months 2 weeks ago by Phil Ford.

The following user(s) said Thank You: kevinross

Please Log in or Create an account to join the conversation.

- C.Morris

-

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 3

8 months 2 weeks ago #26925

by C.Morris

Replied by C.Morris on topic Morris Dancer build

11x5.5 for 4s

12x6 for 3s

Or 13x6 3s watch the amps

I believe some have run 5s with 10x5.

12x6 for 3s

Or 13x6 3s watch the amps

I believe some have run 5s with 10x5.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

8 months 2 weeks ago - 8 months 2 weeks ago #26926

by Phil Ford

Replied by Phil Ford on topic Morris Dancer build

My trial run-up was pushing it a bit at 12x8 on 4 cells. The latest motor being heavier I think has helped as on first impressions of a complete dry assembly it was a little tail heavy. Although I thought that 11x 7 or 11x5.5 would be more in the "ball park". (the latter - Americanism)

Yesterday, Tuesday I had fun slotting all the surfaces. Most were easy with a scalpel except slotting the trailing edge of the wing. Hard balsa? Anyway once all dry fitted time for the CA thin for the wing. All went well sort off. One aileron is slightly further away from the trailing edge than it was when dry fitted. I think it was eagerly flexing the aileron too much went glueing.

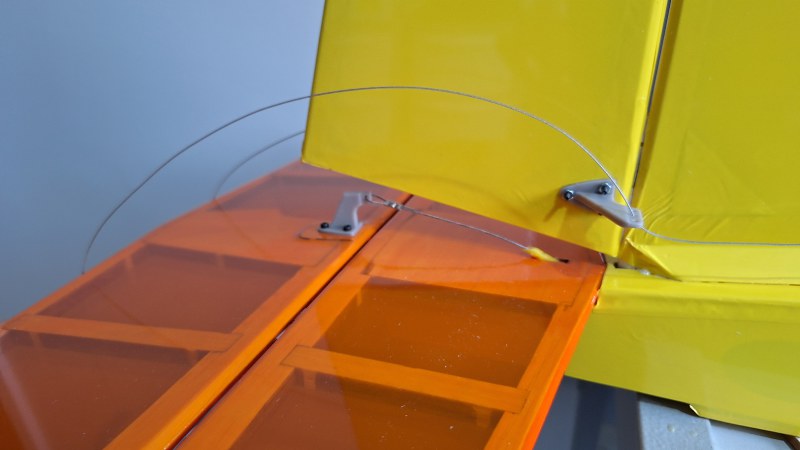

Today, is gluing the tail and setting up the aileron pull pull wires.

And Yes, the guest bedroom is a unofficial store of model aircraft.

Yesterday, Tuesday I had fun slotting all the surfaces. Most were easy with a scalpel except slotting the trailing edge of the wing. Hard balsa? Anyway once all dry fitted time for the CA thin for the wing. All went well sort off. One aileron is slightly further away from the trailing edge than it was when dry fitted. I think it was eagerly flexing the aileron too much went glueing.

Today, is gluing the tail and setting up the aileron pull pull wires.

And Yes, the guest bedroom is a unofficial store of model aircraft.

Last edit: 8 months 2 weeks ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

8 months 2 weeks ago - 8 months 2 weeks ago #26927

by Phil Ford

Replied by Phil Ford on topic Morris Dancer build

Control wires fitting. I have discovered that "large" horns are too big for the upper elevator. Rudder gets in the way. Glad I found this out before gluing in the rudder and tail fin. After a few measurements I found that the horn cut down so only the first hole is left (18mm from base) will do the job. That will also match the outermost hole of the servo arm. Effectively close to 1 to 1 pull. The horn on the underside not a problem, I just moved the wire down to the first hole. See images

Job has come to halt. Cannot find my bag of 2mm clevises that I put somewhere safe. I bet that when I go and get some more the originals will turn up. Grrrr...

Job has come to halt. Cannot find my bag of 2mm clevises that I put somewhere safe. I bet that when I go and get some more the originals will turn up. Grrrr...

Last edit: 8 months 2 weeks ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

8 months 1 week ago - 8 months 1 week ago #26928

by Phil Ford

Replied by Phil Ford on topic Morris Dancer build

Today has gone fairly well. Pull wires all complete on the elevator and rudder. Ailerons have been connected with 2mm rods, clevises and nylon snap locks. Replaced the wheels with 2 1/2 inch foamies. ESC is now a Mantis 65amp. Prop is APC 11x7. A slight mod for the tail. Made up a tail wheel instead of the skid. It'll work or it won't! Found a new yellow spinner in my stock drawers.

Out in the drive for power up test. Fully charged 3 and 4 cells

3 cell gave me 500 watts. 32 amps. The 4 cell was 300 watts at half throttle. Full throttle was above 630 watts, I think I saw on the amp meter like 49 amps, but I only held it for a second or two as I was trying to hang on to it and the TX in the other hand.

Now with the wing fitted I could set up the ailerons and take some photos. I have left the firewall clear of covering as I have a suspicion I may have to add some sticky weights. The CG is 100mm to 140mm. Fly it and see the preferential position.

Out in the drive for power up test. Fully charged 3 and 4 cells

3 cell gave me 500 watts. 32 amps. The 4 cell was 300 watts at half throttle. Full throttle was above 630 watts, I think I saw on the amp meter like 49 amps, but I only held it for a second or two as I was trying to hang on to it and the TX in the other hand.

Now with the wing fitted I could set up the ailerons and take some photos. I have left the firewall clear of covering as I have a suspicion I may have to add some sticky weights. The CG is 100mm to 140mm. Fly it and see the preferential position.

Last edit: 8 months 1 week ago by Phil Ford. Reason: Update

The following user(s) said Thank You: kevinross

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.274 seconds

Latest Posts

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Brian

- 5 days 16 hours ago

-

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 2 weeks 23 hours ago

-

©

2009 - 2025

WMAC PCF Design