- Posts: 1258

- Thank you received: 428

Phase 5 by Chris Foss

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

7 years 6 months ago #16247

by MikeSeale

Replied by MikeSeale on topic Phase 5 by Chris Foss

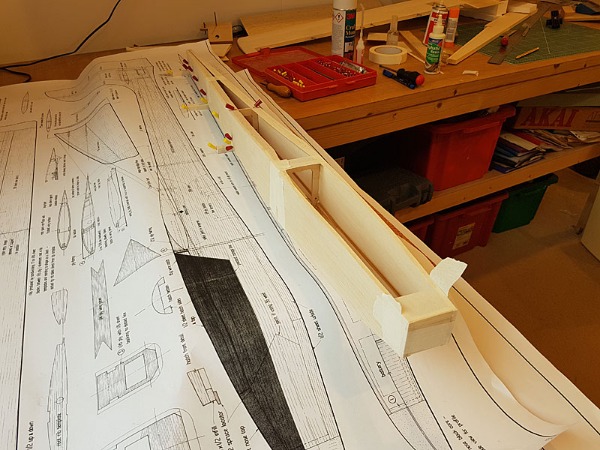

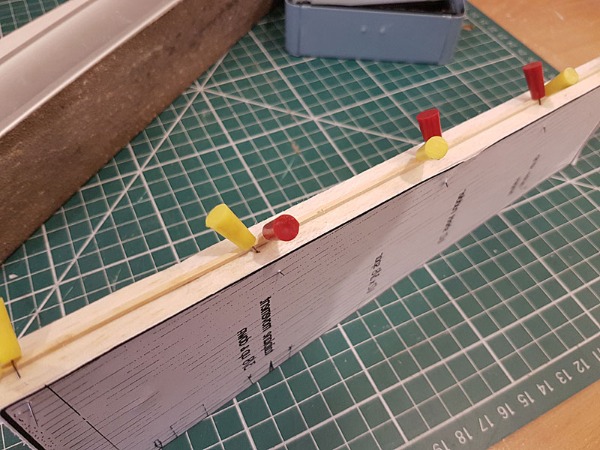

You'll remember from earlier posts that the tailplane had been cut from foam? Last night I skinned them with 1/32 balsa using Gorilla glue like I did for the wings. Today was time to face the leading edge with 1/4 balsa and the trailing edge with 1/16 x 1/16 spruce. The tips have a core of 1/16 ply and 1/8 balsa.

And I've made a start on the pockets for the tubes in the tail. A chunk of foam/balsa was cut out. The base is then lined with 3/32 at the front and 1/8 at the rear which seems to place the tubes about central in the slot. The sides are faced with 1/32 and scraps hold these sides in place while the glue dries.

And I've made a start on the pockets for the tubes in the tail. A chunk of foam/balsa was cut out. The base is then lined with 3/32 at the front and 1/8 at the rear which seems to place the tubes about central in the slot. The sides are faced with 1/32 and scraps hold these sides in place while the glue dries.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

7 years 6 months ago #16248

by MikeSeale

Replied by MikeSeale on topic Phase 5 by Chris Foss

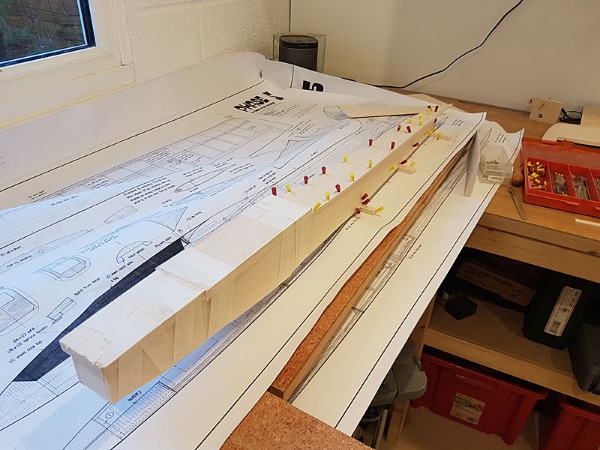

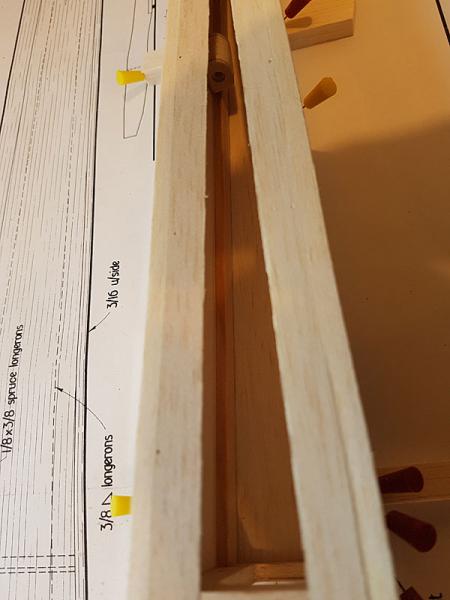

The fuselage is a simple affair. A more modern design would use a lot less wood for lightness and to reduce costs. However, this model is going to be flown heavy in strong winds and using 1/2 inch blocks of balsa as designed will make it very strong.

The fuselage has just three formers, one in the nose, one in front of the wing and one behind the wing. The fuselage is built inverted over the plan. Fuselage sides have 1/8 x 3/8 spruce stringers along their upper surface and 3/8 triangular section balsa along the bottom surface.

The fuselage has just three formers, one in the nose, one in front of the wing and one behind the wing. The fuselage is built inverted over the plan. Fuselage sides have 1/8 x 3/8 spruce stringers along their upper surface and 3/8 triangular section balsa along the bottom surface.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

7 years 6 months ago #16249

by MikeSeale

Replied by MikeSeale on topic Phase 5 by Chris Foss

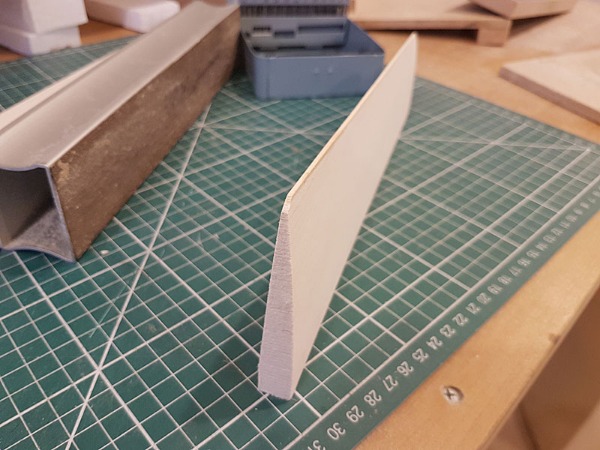

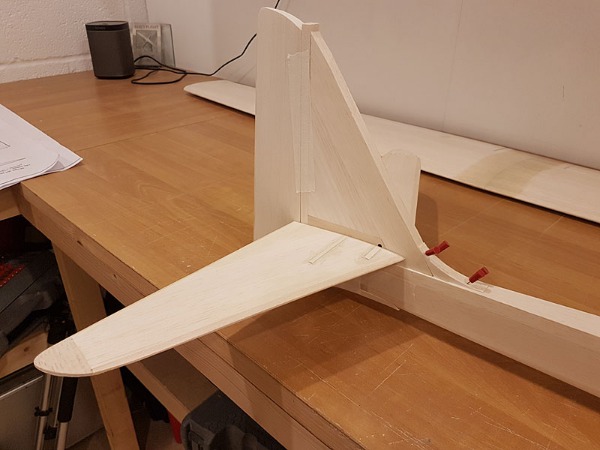

Rudder is a solid piece of 1/2 inch balsa. I added a 1/16 x 1/16 piece of spruce along the centre of the trailing edge to give me a nice sharp and hard surface once sanded

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

7 years 6 months ago #16250

by MikeSeale

Replied by MikeSeale on topic Phase 5 by Chris Foss

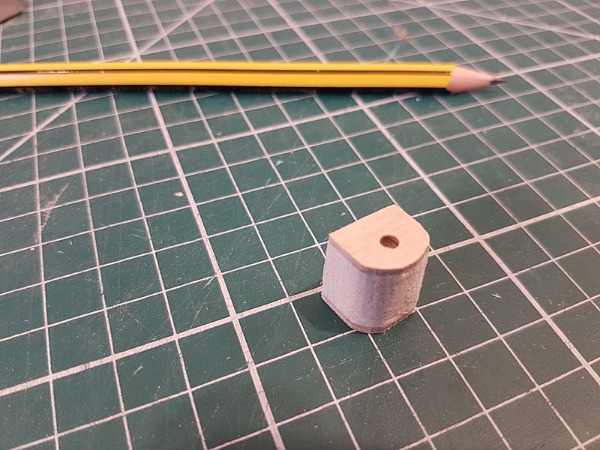

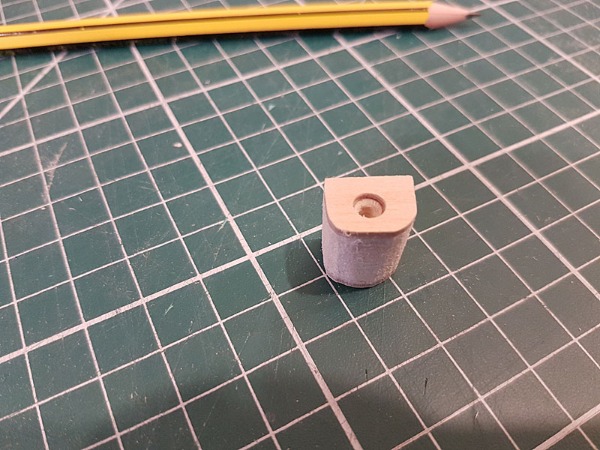

The plan calls for a closed loop for the rudder control. But I'm not a fan of closed look and will be using a carbon rod in a PTFE tube. Holes were pre-drilled in the formers but I wanted another support along the tail boom. The trouble is that the elevator pushrod also has to move freely in that space so I could not put another former in there. It's also very tight and adding a support after sheeting was not going to be possible. So I've made a thick support of 1/2 inch balsa faced with 1/16 ply. A 3mm hole is drilled through and then a 5mm hole is part-drilled through the block. When the carbon rod and PTFE tube is passed through the two formers it naturally lines up with the 5mm guide hole to pass through the 3mm hole at the other side of the balsa block - well that's the plan anyway!

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- MikeSeale

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

7 years 6 months ago #16260

by MikeSeale

Replied by MikeSeale on topic Phase 5 by Chris Foss

The all moving tail has ended up being rock solid. I don't know if it's due to using over-sized piano wire or if it's because I've developed better skills in the 10 years since the last AMT I did. Either way I'm happy. I used my pin boards to line up the AMT box vertically while I glued the tubes into the elevator halves lying flat on the boards. I was just hoping that it would work...and using 5-minute epoxy you don't have long to get it right. Fortunately the tail ended up perfect and it lines up with the wing to within a fraction of a degree.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3163

- Thank you received: 903

7 years 6 months ago - 7 years 6 months ago #16266

by Phil Ford

Replied by Phil Ford on topic Phase 5 by Chris Foss

Looking good Mike. AMT? your idea or fancied something different?

Cannot start on my Phase 6 due to my workbench becoming a potting shed/greenhouse till end of Spring. Never mind I have another new project I can do in the meantime.

Never mind I have another new project I can do in the meantime.

Cannot start on my Phase 6 due to my workbench becoming a potting shed/greenhouse till end of Spring.

Last edit: 7 years 6 months ago by Phil Ford.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.298 seconds

Latest Posts

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 1 day ago

-

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 2 weeks 12 hours ago

-

©

2009 - 2025

WMAC PCF Design