- Posts: 3163

- Thank you received: 903

Stearman build

- Phil Ford

-

- Offline

- Administrator

-

Less

More

4 years 10 months ago - 4 years 10 months ago #23685

by Phil Ford

Replied by Phil Ford on topic Stearman build

Strange how sometimes we think we are doing correctly and then a second look and think, "That's not right".  Sometimes we are able to recover from an error. I had a similar moment when drilling a firewall for an engine conversion.

Sometimes we are able to recover from an error. I had a similar moment when drilling a firewall for an engine conversion.

Last edit: 4 years 10 months ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- kevinross

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

4 years 10 months ago #23702

by kevinross

Replied by kevinross on topic Stearman build

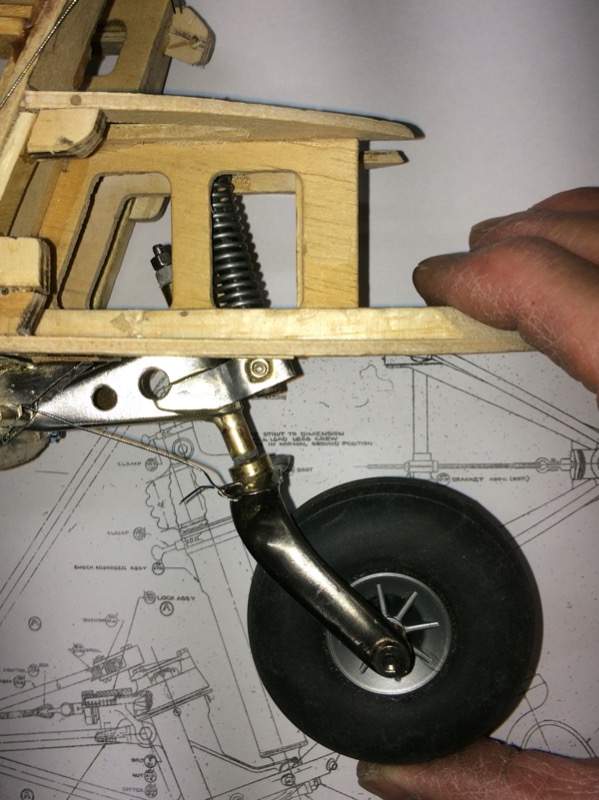

I had said -" I'm shying away from a sprung assembly" - Well my thoughts got the better of me so have fabricated a swinging arm. Next i have to figure out the springy bit.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- kevinross

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

4 years 10 months ago #23703

by kevinross

Replied by kevinross on topic Stearman build

continued

The following user(s) said Thank You: 4Pedalsfly, Brian

Please Log in or Create an account to join the conversation.

- JonTappin

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1179

- Thank you received: 265

4 years 10 months ago #23704

by JonTappin

Replied by JonTappin on topic Stearman build

Lovely work Kevin!

Please Log in or Create an account to join the conversation.

- kevinross

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

4 years 10 months ago #23712

by kevinross

Replied by kevinross on topic Stearman build

I know this Audi jargon has no bearing but this sounds appropriate

Tail sprung durch Technik !

Tail sprung durch Technik !

The following user(s) said Thank You: 4Pedalsfly, Phil Ford, Brian

Please Log in or Create an account to join the conversation.

- kevinross

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

4 years 10 months ago - 4 years 10 months ago #23737

by kevinross

Replied by kevinross on topic Stearman build

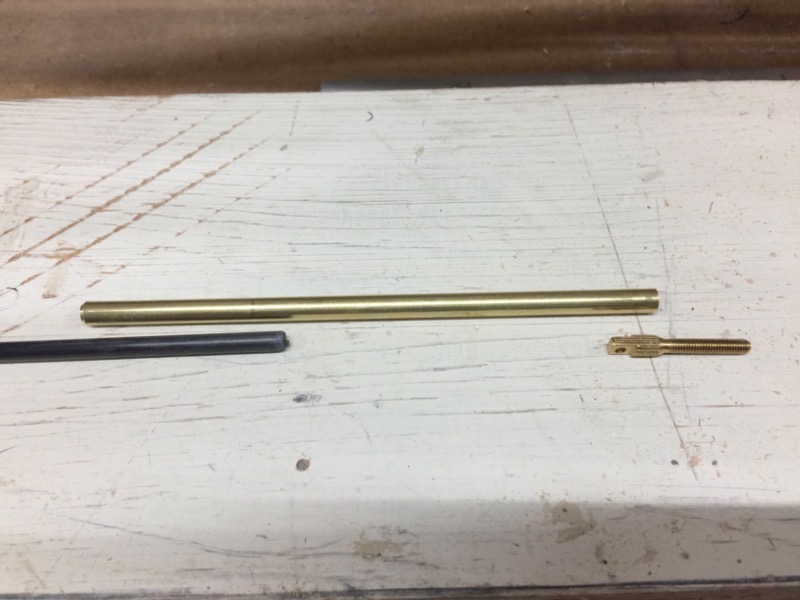

Little space for large diameter elevator pushrods at the back end so made these using 4mm solid carbon.

Silver soldered these 3mm fittings inside brass tube. After cyno gluing, i drilled a couple of micro holes thru the brass wall then crimped a detent to prevent any future movement.

Silver soldered these 3mm fittings inside brass tube. After cyno gluing, i drilled a couple of micro holes thru the brass wall then crimped a detent to prevent any future movement.

Last edit: 4 years 10 months ago by kevinross.

The following user(s) said Thank You: 4Pedalsfly, Phil Ford, Brian

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.292 seconds

Latest Posts

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 1 day ago

-

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 2 weeks 12 hours ago

-

©

2009 - 2025

WMAC PCF Design