- Posts: 803

- Thank you received: 202

Scratch Built Hannibal

- 4Pedalsfly

-

- Offline

- Platinum Member

-

Less

More

8 years 4 months ago #13039

by 4Pedalsfly

Replied by 4Pedalsfly on topic Scratch Built Hannibal

Hi Brian - I have pull - pull on my Extreme Flite "Vanquish" rudder , this is the standard 2 wire system & works well.

If you stand the model on its wing tip & pretend the rudder is the elevator it works just fine, the servo would need

mounting on its side to avoid an awkward twist in the cables.

If you want a vintage look you could have the servo horns mounted externally with servos inside the model.

Hope this helps.

Colin

If you stand the model on its wing tip & pretend the rudder is the elevator it works just fine, the servo would need

mounting on its side to avoid an awkward twist in the cables.

If you want a vintage look you could have the servo horns mounted externally with servos inside the model.

Hope this helps.

Colin

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- kevinross

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

8 years 4 months ago - 8 years 4 months ago #13041

by kevinross

Replied by kevinross on topic Scratch Built Hannibal

Hi Brian

The common closed loop method by attaching each wire directly to a 180deg servo horn works well. The minute you add extra mechanical parts, the more chance of failure. In particular with the method demonstrated (which is only a mock up) would be susceptible to the wire slipping off the turnaround pulley and jamming. If the method was good, it would be adopted by expensive production models. Some designs introduce a lay pivot for the closed loop elevators which is then operated by a short servo link. I had a DB models biplane with that method which was awful. Unless you engineer ball raced auxiliary mechanisms there is no way they will be as smooth as attaching the control wires directly to a ball raced servo.

There is no reason why you cannot mount rudder and elevator servos normally (horizontal ) and run the elev closed loop thru 90deg. However, i do recommend you trial such an installation before covering to optimise the control runs and start with a large servo disc. Then experiment with the attachment points + / - 90 deg to minimise any slack at full surface deflection.

The common closed loop method by attaching each wire directly to a 180deg servo horn works well. The minute you add extra mechanical parts, the more chance of failure. In particular with the method demonstrated (which is only a mock up) would be susceptible to the wire slipping off the turnaround pulley and jamming. If the method was good, it would be adopted by expensive production models. Some designs introduce a lay pivot for the closed loop elevators which is then operated by a short servo link. I had a DB models biplane with that method which was awful. Unless you engineer ball raced auxiliary mechanisms there is no way they will be as smooth as attaching the control wires directly to a ball raced servo.

There is no reason why you cannot mount rudder and elevator servos normally (horizontal ) and run the elev closed loop thru 90deg. However, i do recommend you trial such an installation before covering to optimise the control runs and start with a large servo disc. Then experiment with the attachment points + / - 90 deg to minimise any slack at full surface deflection.

Last edit: 8 years 4 months ago by kevinross.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- kevinross

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

8 years 4 months ago #13042

by kevinross

Replied by kevinross on topic Scratch Built Hannibal

Me again

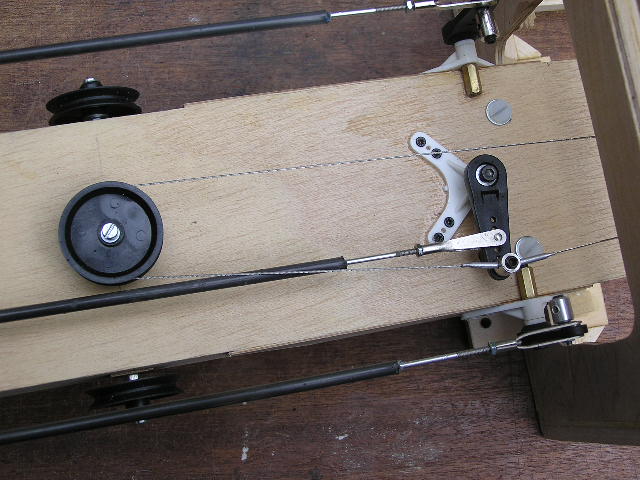

Subsequent to above post, i recalled you had already provisioned for two elevator servos in the vertical plane so using dual standard closed loops for each elevator half is the logical way. If you have searched the internet you may have found something like this attachment. On my large Decathlon (and others) i find that crossing the cables gives a neater installation (especially where the wires pass thru the fuselage) and is better geometrically - minimising slack on full deflection.

Has your radio got the capability to link / mix a 2nd elevator servo - far more preferable to an in line servo reverser

Subsequent to above post, i recalled you had already provisioned for two elevator servos in the vertical plane so using dual standard closed loops for each elevator half is the logical way. If you have searched the internet you may have found something like this attachment. On my large Decathlon (and others) i find that crossing the cables gives a neater installation (especially where the wires pass thru the fuselage) and is better geometrically - minimising slack on full deflection.

Has your radio got the capability to link / mix a 2nd elevator servo - far more preferable to an in line servo reverser

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1044

- Thank you received: 414

8 years 4 months ago #13060

by Brian

Replied by Brian on topic Scratch Built Hannibal

Tail unit and control surfaces fitted. Decided to use the system shown in the video. The servos drive intermediate servo arms via pushrods. The rudder was very easy to set up, a single loop of wire passing from one horn, through the connector on the servo arm and round the pulley and back to to the opposite horn. The rudder was centred as was the rudder servo, the connector was clamped to the wire . A short length of alloy tube crimped to the wire stops the wire being damaged by the clamp screw. On test equal throws each way, and no sign of binding, made it all seem worth while. A bit time consuming to make and assemble the bits, but a doddle to set up. At the moment the wires cross each other at about mid-point in the run. I'll stop them rubbing against each other by running each one through a short length of hard plastic tube where they cross . Each elevator will be fitted up in the same way, The wire runs for the upper elevator horns will be interesting due to the broad chord of the tail plane. Running the wires over small brass pulleys set in the top rear of the fuselage in front of the tail plane might work..

Please Log in or Create an account to join the conversation.

- MikeSeale

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

8 years 4 months ago #13063

by MikeSeale

Replied by MikeSeale on topic Scratch Built Hannibal

If the wire is nylon coated there would be no reason for stopping the wires rubbing against each other. And even if not, the metal to metal rubbing would not be an issue over the lifetime of the model. It's not like the old FM days when metal to metal noise was a problem.

In your first photo I cannot see a crimp...how are you securing the wire?

In your first photo I cannot see a crimp...how are you securing the wire?

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1044

- Thank you received: 414

8 years 4 months ago #13065

by Brian

Replied by Brian on topic Scratch Built Hannibal

Hello Mike, the wire is fed through a piece of alloy tube which is crimped in two places. I'll try to get a better shot of the whole thing.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.278 seconds

Latest Posts

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 1 day ago

-

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 2 weeks 16 hours ago

-

©

2009 - 2025

WMAC PCF Design