- Posts: 1028

- Thank you received: 583

Scratch Built Hannibal

- kevinross

-

- Offline

- Platinum Member

-

Less

More

8 years 1 month ago #13080

by kevinross

Replied by kevinross on topic Scratch Built Hannibal

Hi Brian

I see you have gone for the closed loop design with the turnaround pulley. Very sorry but i can't sit back and see you risk a well built model without offering further advise. I am concerned abut the possibility of failure in this design which has no protection against the closed loop becoming detached from the pulley leading to loss of control.

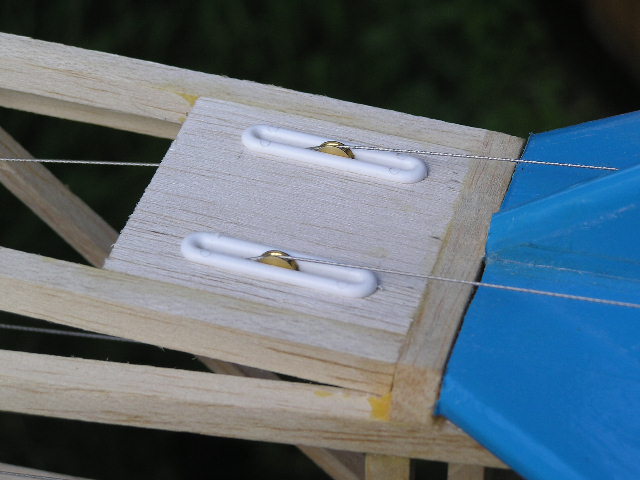

Full size aircraft make extensive use of closed loop systems but every point is protected against the wires jumping off the pulleys. See the attached pic

When your model buffets around the Cashmoor airways the rear fuselage will be subjected to a multitude of stresses which will cause those control runs to stretch / relax with a strong possibility of whipping off the pulleys. I would recommend that you increase the pulley groove depth (for example - glue additional discs top and bottom ) and /or fix small round pillars / guides close to pulleys provide additional safety retention of the control wires.

I see you have gone for the closed loop design with the turnaround pulley. Very sorry but i can't sit back and see you risk a well built model without offering further advise. I am concerned abut the possibility of failure in this design which has no protection against the closed loop becoming detached from the pulley leading to loss of control.

Full size aircraft make extensive use of closed loop systems but every point is protected against the wires jumping off the pulleys. See the attached pic

When your model buffets around the Cashmoor airways the rear fuselage will be subjected to a multitude of stresses which will cause those control runs to stretch / relax with a strong possibility of whipping off the pulleys. I would recommend that you increase the pulley groove depth (for example - glue additional discs top and bottom ) and /or fix small round pillars / guides close to pulleys provide additional safety retention of the control wires.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1044

- Thank you received: 414

8 years 1 month ago #13081

by Brian

Replied by Brian on topic Scratch Built Hannibal

Hi Kevin, I see what you mean about the depth of the pulley grooves. I'll have another look at the set-up with a view to making it a bit safer. Thank you for pointing out a possible failure.

Please Log in or Create an account to join the conversation.

- kevinross

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

8 years 1 month ago #13082

by kevinross

Replied by kevinross on topic Scratch Built Hannibal

Brian

A possible improvement would be to screw three suitable small pulleys similar to these in the attached jpg interlocking (but not touching) as per the positions on the pdf pic.

A possible improvement would be to screw three suitable small pulleys similar to these in the attached jpg interlocking (but not touching) as per the positions on the pdf pic.

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1044

- Thank you received: 414

8 years 1 month ago #13100

by Brian

Replied by Brian on topic Scratch Built Hannibal

Elevator control wires fitted and tested today, full range of movement and no binding, on elevator and rudder. Decided to run the upper elevator wires through the top rear of the fuselage. Lower elevator wires and rudder wires exit through the fuselages sides under the tail plane, the lead outs will be fitted with brass pulleys., similar to those shown. The servos were left running on a servo tester for a half hour or so. No slop in the control surfaces, and all returned to neutral on switch off. Looks quite promising so far.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1044

- Thank you received: 414

8 years 1 month ago #13102

by Brian

Replied by Brian on topic Scratch Built Hannibal

Hi Kevin, since you suggested a method of preventing the control wires from jumping off the pulleys, I've been looking at ways of doing it without adding weight. I don't think that the short wire runs from servo arm to pulley are a problem. Its the possibility that something could interfere with the long wire run from control horn to the pulley. Today I made some cheap and cheerful wire guides, I think they'll work alright.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1044

- Thank you received: 414

8 years 3 weeks ago #13312

by Brian

Replied by Brian on topic Scratch Built Hannibal

Decided to have a go at finishing the front of the Hannibal fuselage with sticky backed aluminium foil. Made some expensive mistakes. The stuff doesn't work well on sealed balsa, doesn't work on tissue doped onto balsa either. However, I found that spraying cellulose primer/filler over the tissue, and covering with film did give a reasonable base to work with. The main tool for applying the foil is a sort of thick pencil made from rolled paper, I got mine from Hobbycraft, pack of three different sizes for £1. . There are several videos about cladding on YouTube, most seem to concentrate on large warbirds with fibreglass structures, and lots of panel and rivet detail I found that the foil is tricky to get started without wrinkling. I wasted quite a lot trying different methods. The one that worked for me was to stick a piece of masking tape on the foil itself. Holding the tape allows the backing to be peeled away without touching the adhesive on the foil. Once the foil is positioned, its simply(?) a matter of gently "inviting" the foil to come away from the backing while stroking it down with the paper pencil. The pencil itself needs to have a radius sanded on one end, this helps to get the foil to lay down smoothly. The videos of cladding show the alloy being dry sanded with 320 grit W+D, this might be OK for thicker films, it didn't work with my stuff, and bubbles and wrinkles sanded through. Getting the foil off is something else. A process involving an old artists bristle brush, lots of acetone, and a good deal of "language". It took over an hour to strip the front hatch cover.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.327 seconds

Latest Posts

-

-

- Can we fly turbines again yet??

- In Main Forum / Announcements

- by Remedii1

- 2 hours 12 minutes ago

-

©

2009 - 2025

WMAC PCF Design