- Posts: 803

- Thank you received: 202

Gromit's Phase 5 Build

- 4Pedalsfly

-

- Offline

- Platinum Member

-

Less

More

7 years 3 weeks ago - 7 years 3 weeks ago #17709

by 4Pedalsfly

Replied by 4Pedalsfly on topic Gromit's Phase 5 Build

Quote from Chris

"I've made a little mini hotwire cutter that I used to cut out the servo holes, wing bolt hard points and the servo wire trench".

Good to see you back on the forum.

I'm currently messing about with a foam flying wing & would be interested in details of your mini hot wire cutter.

I've been hacking out holes etc with saw / blades.

Thanks

Colin.

"I've made a little mini hotwire cutter that I used to cut out the servo holes, wing bolt hard points and the servo wire trench".

Good to see you back on the forum.

I'm currently messing about with a foam flying wing & would be interested in details of your mini hot wire cutter.

I've been hacking out holes etc with saw / blades.

Thanks

Colin.

Last edit: 7 years 3 weeks ago by 4Pedalsfly.

Please Log in or Create an account to join the conversation.

- MikeSeale

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

7 years 3 weeks ago #17710

by MikeSeale

Replied by MikeSeale on topic Gromit's Phase 5 Build

Good to see progress being made. The fuselage design is simple and takes shape very quickly so you might be carving balsa before too long. To answer a few of your questions:

1. The pieces of lead are the same length as the ballast box so they do not rattle back and fore. A couple of pieces of foam below and above the lead stops them rattling up and down or sideways.

2. I think that shaping the wing with ailerons in place is a good idea but does make it a little more awkward later...swings and roundabouts.

3. My rudder pushrod exits directly below the bellcrank but it can go anywhere if it does not foul the elevator control. In the attached image you can see I've marked the access hole for the elevator bellcrank in blue.

Phil...I've used a 1.5mm carbon pushrod for the rudder, running through a plastic guide tube. At the end I've bound a piece of wire to the carbon and glued it with thin CA. The joint is covered with a small piece of heatshrink. An L-bend is used for the ink to the rudder horn. This setup is, IMHO, a lot simpler than a closed loop setup and has zero slop compared to a closed loop setup. I think it is probably just as light as a closed loop setup too. If you do decide to use a closed loop setup you will experience the joy of threading those wires down a narrow fuselage and trying to ensure that they do not bind with the elevator pushrod.

1. The pieces of lead are the same length as the ballast box so they do not rattle back and fore. A couple of pieces of foam below and above the lead stops them rattling up and down or sideways.

2. I think that shaping the wing with ailerons in place is a good idea but does make it a little more awkward later...swings and roundabouts.

3. My rudder pushrod exits directly below the bellcrank but it can go anywhere if it does not foul the elevator control. In the attached image you can see I've marked the access hole for the elevator bellcrank in blue.

Phil...I've used a 1.5mm carbon pushrod for the rudder, running through a plastic guide tube. At the end I've bound a piece of wire to the carbon and glued it with thin CA. The joint is covered with a small piece of heatshrink. An L-bend is used for the ink to the rudder horn. This setup is, IMHO, a lot simpler than a closed loop setup and has zero slop compared to a closed loop setup. I think it is probably just as light as a closed loop setup too. If you do decide to use a closed loop setup you will experience the joy of threading those wires down a narrow fuselage and trying to ensure that they do not bind with the elevator pushrod.

The following user(s) said Thank You: Phil Ford,

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3163

- Thank you received: 903

7 years 3 weeks ago - 7 years 3 weeks ago #17712

by Phil Ford

Replied by Phil Ford on topic Gromit's Phase 5 Build

Come to think of it Mike your spot on there. I had the same awful feeling too about the wires. Carbon the way to go. Thanks.

Last edit: 7 years 3 weeks ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- MikeSeale

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1258

- Thank you received: 428

7 years 3 weeks ago #17713

by MikeSeale

Replied by MikeSeale on topic Gromit's Phase 5 Build

I get my guide tube from Hyperflight:

www.hyperflight.co.uk/products.asp?cat=M...als&subcat=PTFE+Tube

If you do go that route let me know and we can split the shipping cost because I will need some more carbon and tube soon.

And the L-bend is wrapped with kevlar or cotton thread before CA'ing in place. Let me know if you'd like to see how I do it?

www.hyperflight.co.uk/products.asp?cat=M...als&subcat=PTFE+Tube

If you do go that route let me know and we can split the shipping cost because I will need some more carbon and tube soon.

And the L-bend is wrapped with kevlar or cotton thread before CA'ing in place. Let me know if you'd like to see how I do it?

The following user(s) said Thank You: Phil Ford

Please Log in or Create an account to join the conversation.

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

7 years 3 weeks ago #17714

by

Replied by on topic Gromit's Phase 5 Build

A bit of a rush to try and get things done before lunch today, but the bell crank came out okay, and I managed to sand the wing tips down, but not profiled the ends yet.

Please Log in or Create an account to join the conversation.

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

7 years 3 weeks ago - 7 years 3 weeks ago #17715

by

Hi Colin,

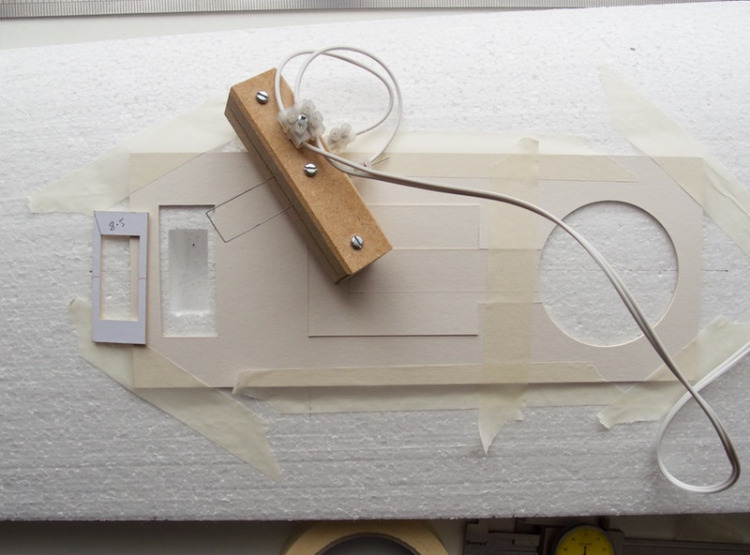

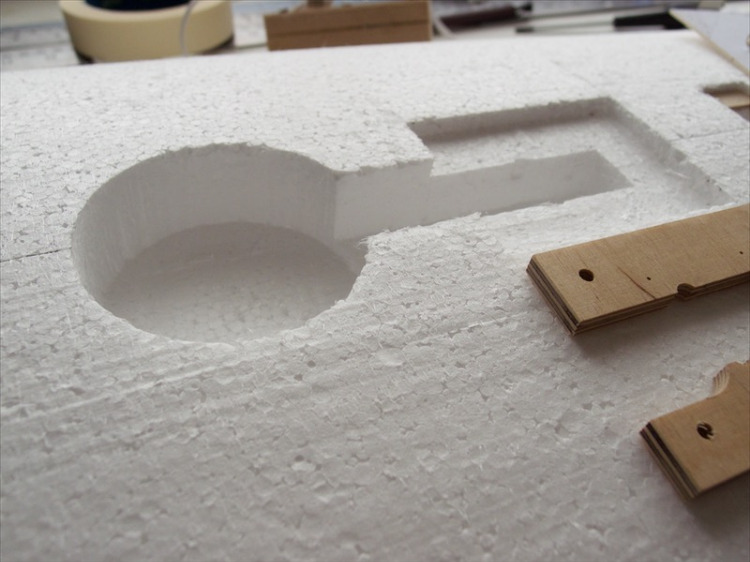

This is the one I used on the Atlas for the servos and retracts, it's just a bent bit of guitar string sandwiched between two bits of MDF, that sets the depth of the cut, and then just follow the template.

It did a neat job:

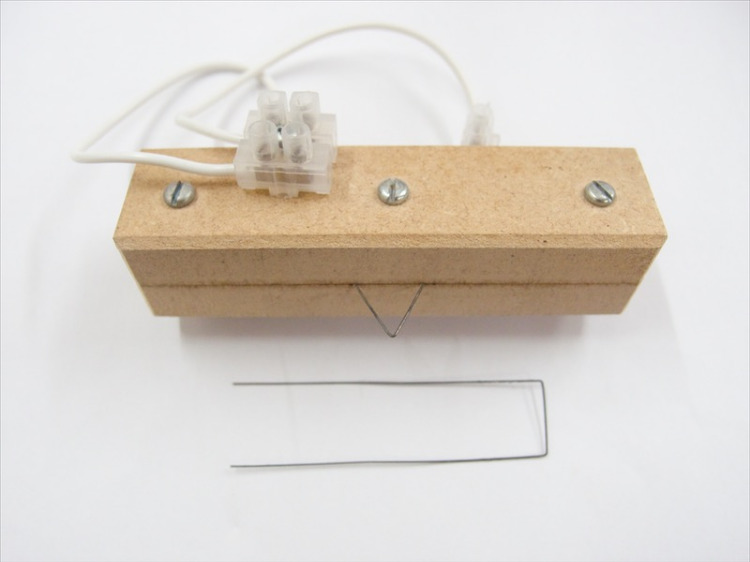

On the Phase 5 I made a second 'cutter' V shaped that was much better for cutting the servo wire trenches.

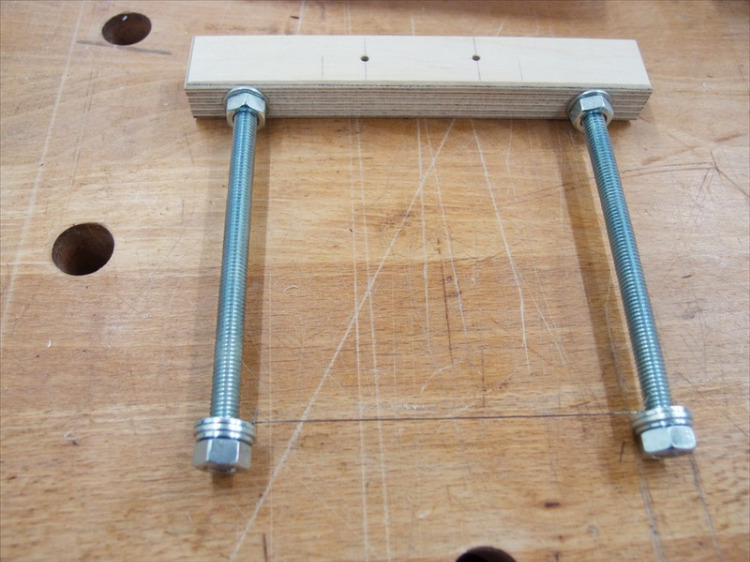

The last one is a hand held bow, the wire is tensioned by screwing down the bolts, it's naff and I need to make something better, but I also keep thinking I might take a punt at one of these: hobbyking.com/en_us/hot-wire-foam-cutter...ter-kit-eu-plug.html

Replied by on topic Gromit's Phase 5 Build

4Pedalsfly wrote: Quote from Chris

"I've made a little mini hotwire cutter that I used to cut out the servo holes, wing bolt hard points and the servo wire trench".

Good to see you back on the forum.

I'm currently messing about with a foam flying wing & would be interested in details of your mini hot wire cutter.

I've been hacking out holes etc with saw / blades.

Thanks

Colin.

Hi Colin,

This is the one I used on the Atlas for the servos and retracts, it's just a bent bit of guitar string sandwiched between two bits of MDF, that sets the depth of the cut, and then just follow the template.

It did a neat job:

On the Phase 5 I made a second 'cutter' V shaped that was much better for cutting the servo wire trenches.

The last one is a hand held bow, the wire is tensioned by screwing down the bolts, it's naff and I need to make something better, but I also keep thinking I might take a punt at one of these: hobbyking.com/en_us/hot-wire-foam-cutter...ter-kit-eu-plug.html

Last edit: 7 years 3 weeks ago by .

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.301 seconds

Latest Posts

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 1 day ago

-

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 2 weeks 7 hours ago

-

©

2009 - 2025

WMAC PCF Design