- Posts: 1045

- Thank you received: 415

3D Printing

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

5 years 11 months ago #21538

by Brian

Replied by Brian on topic 3D Printing

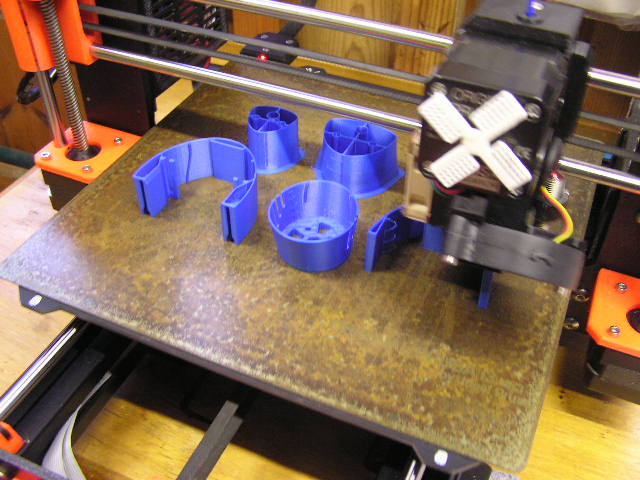

The print process slowed up a bit yesterday. On Friday night, I'd left the printer working on ten parts for the Joker's wing and flaps, the program predicted twenty three hours. I was disappointed to find the printer hadn't completed the job. It had stopped printing at a height of about 60mm. The display was reading a time in excess of 23 hours, so the failure to print was due to lack of filament. I checked the extruder and the filament was loaded alright, I reheated the nozzle area to around 260 degrees just in case the nozzle was blocked, usually this produces a few drops of melted plastic. This time it didn't, even probing with a tiny needle didn't improve things at all. I tried to clear the extruder by unloading the filament, that's when I found the cause of the print failure, the extruder motor wasn't driving the filament. My fault, when I assembled the rebuilt extruder head, the filament drive gear has a tiny grub screw that locates on a flat on the motor shaft. This screw is only accessible with a long Allen key, unfortunately all my long keys are ball ended, so getting a screw really tight isn't an option. At the time of the assembly I'd thought of using Loctite, but I couldn't find it, so I forgot all about it. I suppose I've been pretty lucky so far, the screw only came loose after a lot of printing. Anyway, its now screwed in with a proper plain ended Allen key and for peace of mind, it has a drop of Loctite as well. The next print stage will be the six parts that form the fuselage, I'll have to wait until six 'o clock tomorrow to find out if ot has worked.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

5 years 11 months ago #21542

by Brian

Replied by Brian on topic 3D Printing

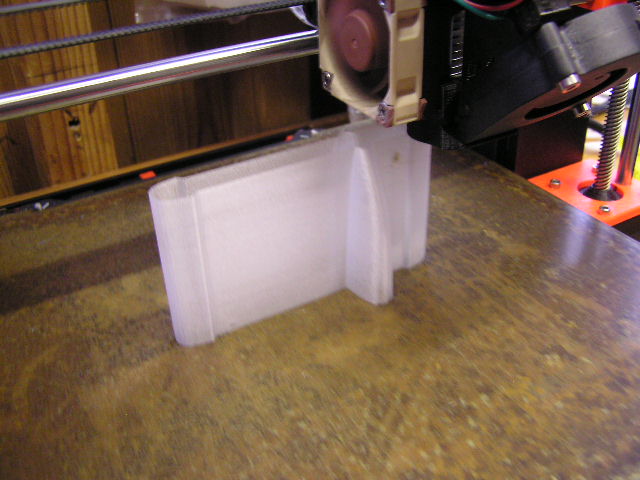

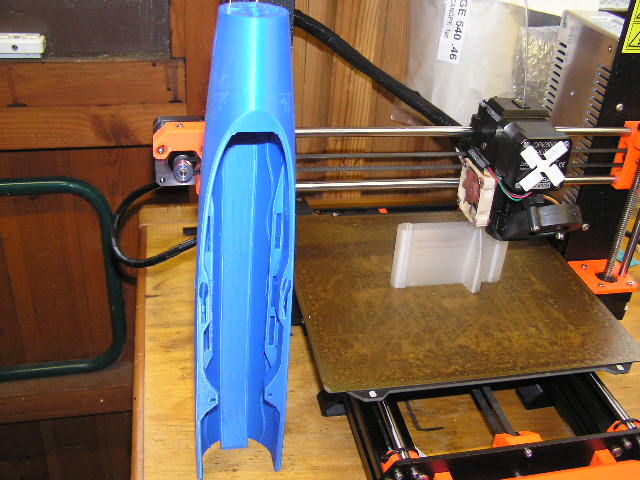

Checked the progress after three hours, I think the Loctite and newly tightened grub screw are working well. Six pieces of fuselage on the build plate, bit fuzzy as it moves quite quickly,and I didn't use flash for the shot, the actual colour of the print is a bit "bluer" than shown in the photo. More printing tomorrow, with a bit of luck.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

5 years 11 months ago #21544

by Phil Ford

Replied by Phil Ford on topic 3D Printing

Them bits look quite good. Can't wait to see the finished article.

Please Log in or Create an account to join the conversation.

-

- New Member

-

Less

More

- Thank you received: 0

5 years 11 months ago - 5 years 11 months ago #21553

by

Replied by on topic 3D Printing

Good Luck Brian. You have more patience then me. Also its good idea to clean your toothed gear which feeds your filament with a small paint brush, which dose get clogged up with filament dust.

Last edit: 5 years 11 months ago by .

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

5 years 11 months ago - 5 years 11 months ago #21554

by Brian

Replied by Brian on topic 3D Printing

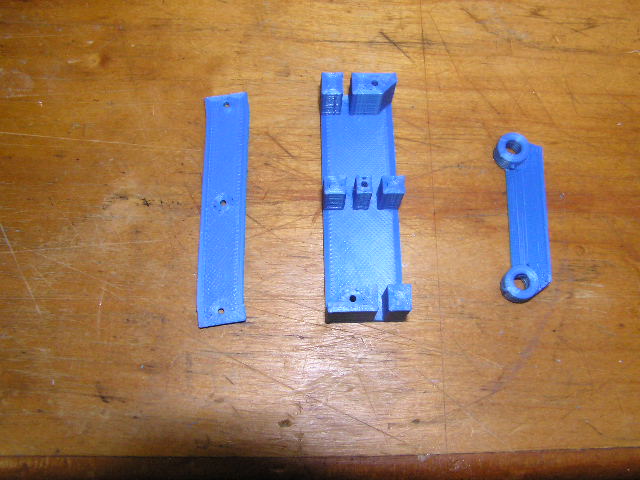

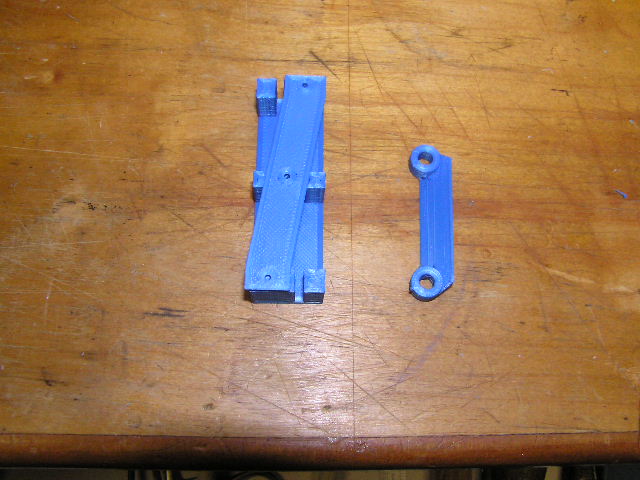

The final parts for the Joker printed out today, happy to see that last night's printing had been a success. There are still some niggles with the print quality. According to the troubleshooting guide, it might be something to do with the distance the filament being retracted coupled with the speed of retraction. I'll have to juggle the settings again, and print a couple of the smaller parts to test it out. The fuselage sections have printed with surprisingly accurate joints, they are so good that the whole fuselage can be "plugged" together without glue. Today's parts are the servo covers which are printed as joined pairs, the servo mount for the elevator servos and the wing joining strap. All the holes are generated during the print process, no drilling required at all. I won't be able to assemble the fuselage until I get a delivery of 6mm carbon tube, this has to be threaded through holes in four sections of the fuselage, and as the holes are a good fit on a 6mm drill bit, the slightest misalignment on assembly will prevent the tube from fitting the full length of the rear fuselage.

Thanks for the tip about keeping the extruder gears clean Alan, fortunately the new design extruder I'm using has a good view of the gears without having to take anything apart, I can get a modified toothbrush into the space quite nicely. If I can remember to do it!

Thanks for the tip about keeping the extruder gears clean Alan, fortunately the new design extruder I'm using has a good view of the gears without having to take anything apart, I can get a modified toothbrush into the space quite nicely. If I can remember to do it!

Last edit: 5 years 11 months ago by Brian.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

5 years 11 months ago #21555

by Phil Ford

Replied by Phil Ford on topic 3D Printing

Good stuff Brian. So when we can expect the maiden voyage into the atmosphere?

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.316 seconds

Latest Posts

- No posts to display.

©

2009 - 2026

WMAC PCF Design