- Posts: 3163

- Thank you received: 903

Christmas Curare EP

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Firstly you have to use a double arm for the pull pull maximum width 44mm. Using the link connectors on the outside holes equals 40 mm the same as near minimum of the rudder horns. Manual shows clevises screwed on to couplings with pull wire threaded through. All done, hello we have a problem.

The clevis and link nearest the elevator servo won't clear it! Pondered this issue for while and decided to forget the manual and do it my way to achieve the proper outcome.

Do away with clevises use the connectors and slide the wire links through the connectors. This now gives some adjustment if needed to the pull pull and also the wire just slides by the elevator servo body. See images.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

- Posts: 3163

- Thank you received: 903

Following the manual instructions with respect to the nose leg length (112mm) Wrong again! Wheel collided with the rear of the gear bay. Had to cut out 18 mm to clear.

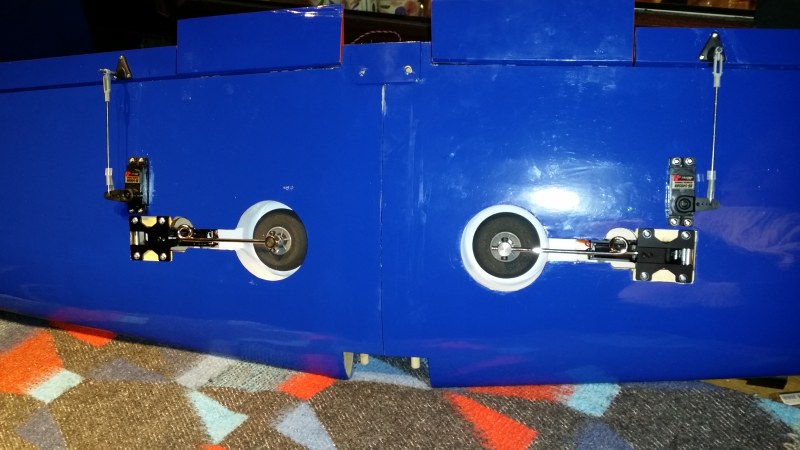

Wings completed. Flaps were a bit of fiddle and again I use some parts from the kit and made up the linkage my way. Again this makes for minute adjustments if needed. See images.

Please Log in or Create an account to join the conversation.

- MikeSeale

-

- Offline

- Platinum Member

-

- Posts: 1258

- Thank you received: 428

You also have a little movement on the rudder horns where you can bring them in a little bit more and then bring the linkages closer to the centre on the servo output arm

Please Log in or Create an account to join the conversation.

- JonTappin

-

- Offline

- Platinum Member

-

- Posts: 1179

- Thank you received: 265

PhilF51 wrote:

The clevis and link nearest the elevator servo won't clear it! Pondered this issue for while and decided to forget the manual and do it my way to achieve the proper outcome.

Do away with clevises use the connectors and slide the wire links through the connectors. This now gives some adjustment if needed to the pull pull and also the wire just slides by the elevator servo body. See images.

Or just pack one servo up so the arms clear each other

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

- Posts: 3163

- Thank you received: 903

If, as per earlier versions the user had to assemble the snake bracket then I could've raised the elevator servo higher (if I foresaw the issue in the first place

Anyway it all works now. I'll grind off the excess rudder horn to make it a bit tidier.

Info: There was no guidance on the horn length settings.

Please Log in or Create an account to join the conversation.

- JonTappin

-

- Offline

- Platinum Member

-

- Posts: 1179

- Thank you received: 265

One of the problems with the way you have done it is that the servo arm can twist with the closed loop load being offset from the centre of the servo arm.

Also personally I have never liked those clamp connectors, I always throw them away. They are for people who can't solder their linkages

Please Log in or Create an account to join the conversation.

Latest Posts

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 1 day ago

-

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Phil Ford

- 2 weeks 15 hours ago

-

.jpg)

.jpg)