- Posts: 1045

- Thank you received: 415

3D Printing

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

3 years 2 months ago #26080

by Brian

Replied by Brian on topic 3D Printing

The past couple of weeks I've had temperatures as high as 45.7°C in my shed. I should have known better than to keep "pressing on" with some printed parts. The added cooling to the extruder motor kept things going, and putting an old 12V fan close to the printer kept things reasonable. Unfortunately not quite enough. Today I closely examined the parts made over the last week or so, and scrapped the lot. I'll start up again when it isn't quite so hot. When it comes to compensating for the ambient temperature, there are no values in the tables provided for the printer/model, seems to be a suck it and see kind of arrangement. The rejected parts were either warped or showing patches of poor finish. The sellers of LW-PLA assure the buyer that when printed, the material is "easy to sand". Perhaps they have never tried to sand a wing skin that is merely 0.45mm thick.

The following user(s) said Thank You: Phil Ford

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

3 years 2 months ago - 3 years 2 months ago #26081

by Phil Ford

Replied by Phil Ford on topic 3D Printing

Although there is an upside to extreme heat. I left a canopy in it for 15 mins in the back garden at 1pm on Thursday and then quickly placed it on the cockpit shell and it now fits perfectly. :lol:

Last edit: 3 years 2 months ago by Phil Ford.

The following user(s) said Thank You: 4Pedalsfly, Brian

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

2 years 4 months ago - 2 years 4 months ago #26519

by Brian

Replied by Brian on topic 3D Printing

I've found that the major snag in building a model from 3D printed lighweight PLA is that the assembly/gluing is pretty tricky. The parts are fragile and need to be held very carefully. Trial fitting the parts is OK, but when the glue is applied, the assembly has to be quick and accurate, and it isn't always a 100% fit after gluing. I printed the free LabPrint Piper 3J Cub some time ago, since abandoned as a lost cause due to the cumulative inaccuracies in assembling the fuselage. I wondered if there was an alternative to "SuperGlue". I'm currently remaking the Cub with a new set of printed parts. I'm using DeLuxe Materials Canopy Glue. I use a small bottle fitted with a fine tube, the joints are coated on both sides and the parts gently assembled. The glue allows plenty of time for adjustment and a bit of "jigging" with an assortment of balsa blocks and lead weights holds everything in place. So far the fuselage has gone together with no twists or warps, the joints aren't absolutely perfect, but they are a lot better than those made with Cyano. The canopy glue is very economical in use, and is quick and easy to clean up with a damp tissue. Might manage to finish this Cub after all.

Last edit: 2 years 4 months ago by Brian. Reason: Spelling

The following user(s) said Thank You: 4Pedalsfly

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

2 years 2 weeks ago #26652

by Brian

Replied by Brian on topic 3D Printing

The free downloaded Cub from 3DLabPrint has now gone to a good home and I have found another model to play with. I saw a video of a 50mm EDF Hawk , it seemed to perform very well (everyone else's 3D printed models always do) I bought the files to print the model, unfortunately the only working files are in G-Code, the supplied STL files are corrupted and cannot be used. I've tried to repair these files using Meshmixer with no success, I sent the files to an outfit that claimed they could fix the problems and I'd be able to print from them, that didn't work either. I contacted the designer, the result was an interesting dialogue which had no bearing on the problem whatsoever. I have printed a set of parts to test the supplied G-Codes, the result is definitely "Hawk shaped" but the finish is awful and I can't do anything to improve the quality. Its a bit late for me to attempt to learn a new set of computer skills which I wouldn't need if the files I bought actually worked. I assume the designer is guarding against illegal copying of the design, if the STL files worked I could have tweaked the quality of the prints with my slicer programme, not only that I could have scaled the files to enable different sizes of the Hawk to be printed. Thankfully the program wasn't too expensive at around £20, but it rankles that I haven't actually got anything I can use.

The following user(s) said Thank You: kevinross

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

2 years 2 weeks ago #26654

by Phil Ford

Replied by Phil Ford on topic 3D Printing

Much of the software around on the Net is created by enthusiasts of coding and given freely to share and modify. Open TX and similar Spin Offs and Android, the latter found in cars, home entertainment equipment and of course phones for example. Some would expect some form of appreciation with a small sum or donation. It's unfortunate Brian that the files you bought do not work although you the end user should be able to tweak them. I suspect it is the way he has coded it so as not be altered and possibly modded by some one even better and probably make it more flexible.

Quite few years ago many people had the same problem. Hundreds of programs created to run on Windows. MAC users moaned. Well that's Apple for you. They want you to use their apps only. Still same today. Not global but some people have created an app so the Windows software will run on a MAC.

Sorry to hear of your loss of £20 and wasted efforts. Maybe stick with balsa?

Quite few years ago many people had the same problem. Hundreds of programs created to run on Windows. MAC users moaned. Well that's Apple for you. They want you to use their apps only. Still same today. Not global but some people have created an app so the Windows software will run on a MAC.

Sorry to hear of your loss of £20 and wasted efforts. Maybe stick with balsa?

The following user(s) said Thank You: Brian

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

2 years 2 weeks ago - 2 years 2 weeks ago #26656

by Brian

Replied by Brian on topic 3D Printing

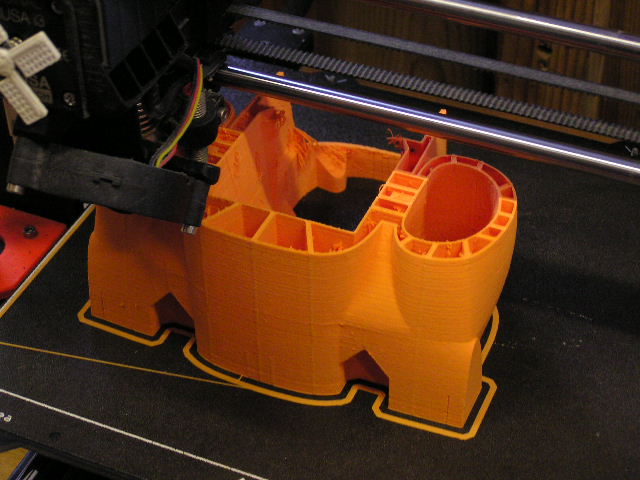

I wrote again to the designer of the dysfunctional program files, and to my surprise I not only got a helpful answer, there was an attachment holding a load of extra files. It took a while for the info to filter through my "system", seems that the key to successful printing is the way the printer is set up. The new files enabled me to alter the printer's profile so that it could cope with the new program. At the moment all seems to be going well and the printer is some six hours into a ten plus hour print. I'm not sure what the additional programs actually do, but the original files printed out very fragile poorly finished single wall items, now all the external surfaces are double wall, still a bit lacking in surface finish, but a lot stronger. The part being printed is the third part of the fuselage for a 5omm EDF Hawk T1, the first two parts have been printed, and the trial fit before gluing up looks pretty good so far. I'll not order any hardware for the Hawk until I've finished building it. The model won't cost a lot to fit out, four 9G servos, 50mm EDF, ESC and a couple of small 4S LiPos.

Last edit: 2 years 2 weeks ago by Brian. Reason: Grammar.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.283 seconds

Latest Posts

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Brian

- 5 days 16 hours ago

-

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 2 weeks 22 hours ago

-

©

2009 - 2025

WMAC PCF Design