- Posts: 1045

- Thank you received: 415

3D Printing

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

3 years 8 months ago - 3 years 8 months ago #25718

by Brian

Replied by Brian on topic 3D Printing

Over the past weeks, I've spent some time on the Prusa printer. The blockage caused when printing wood filled resin caused more problems than I thought. Poking the nozzle with a needle produced a puff of smoke and a black blob of molten resin that narrowly missed my fingers. Nothing improved the situation and I had to strip the print head and clean and re-assemble it.

The last prints I made of an aeroplane were made for the Eclipson Model T, I wasn't impressed by the quality and I didn't know what to do to improve it. Took the easy way out and abandoned the project.

Then in November 2021 I found a glider called Riser on the PlanePrint website. The video of the model in flight was quite encouraging, and being easily persuaded, as well as a bit soft in the head, I bought the programs for printing the model. Over the last few days I've spent a few hours re-calibrating and generally setting up my printer. The trial prints were OK, and I went on to work on the Wingtest program recommended by PlanePrint, this is in the form of a small airfoil section, and the general idea is to tweak the printer's settings until a perfect print is made. Sounds easy, but it took a few hours to get it right.

Having a new spool of lightweight PLA resin, and a working 3D printer, I started to print a part for the Riser glider. That was yesterday. The print failed after three hours. Today I modified the program slightly and the first printed piece of wing finished printing at three this afternoon. I was quite pleased with the result until I weighed it. The manual says "68grams", my part weighed just over 100 grams.

Obviously I have missed something between downloading the STL files and generating the G-Codes from them. I only downloaded the build manual today, lots of A4 sheets to peer at, perhaps the clue will be in there...somewhere?

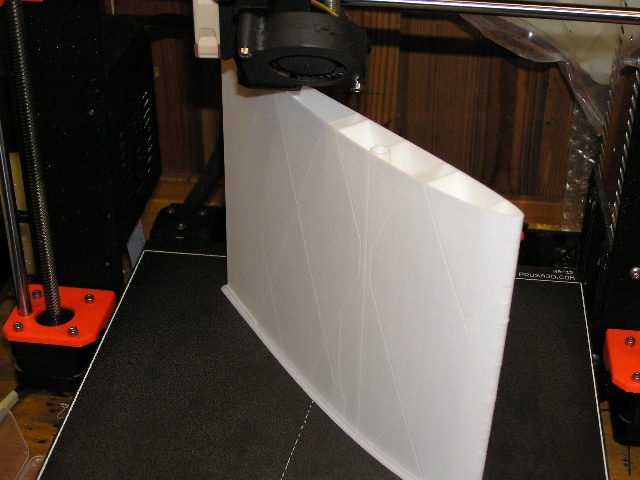

The photo shows the wing part three hours into the print.

The last prints I made of an aeroplane were made for the Eclipson Model T, I wasn't impressed by the quality and I didn't know what to do to improve it. Took the easy way out and abandoned the project.

Then in November 2021 I found a glider called Riser on the PlanePrint website. The video of the model in flight was quite encouraging, and being easily persuaded, as well as a bit soft in the head, I bought the programs for printing the model. Over the last few days I've spent a few hours re-calibrating and generally setting up my printer. The trial prints were OK, and I went on to work on the Wingtest program recommended by PlanePrint, this is in the form of a small airfoil section, and the general idea is to tweak the printer's settings until a perfect print is made. Sounds easy, but it took a few hours to get it right.

Having a new spool of lightweight PLA resin, and a working 3D printer, I started to print a part for the Riser glider. That was yesterday. The print failed after three hours. Today I modified the program slightly and the first printed piece of wing finished printing at three this afternoon. I was quite pleased with the result until I weighed it. The manual says "68grams", my part weighed just over 100 grams.

Obviously I have missed something between downloading the STL files and generating the G-Codes from them. I only downloaded the build manual today, lots of A4 sheets to peer at, perhaps the clue will be in there...somewhere?

The photo shows the wing part three hours into the print.

Last edit: 3 years 8 months ago by Brian. Reason: Comment on photo added.

The following user(s) said Thank You: 4Pedalsfly, Phil Ford

Please Log in or Create an account to join the conversation.

- kevinross

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

3 years 8 months ago - 3 years 8 months ago #25719

by kevinross

Replied by kevinross on topic 3D Printing

Hi Brian

At the last C&Dmfc meeting i attended (pre Covid) there were a couple of members exploiting 3D printing with good success and displayed several good examples including a nice Mustang.

Would you like me to try and put you in contact with these guys with view to reducing your R & D ?

Kevin

At the last C&Dmfc meeting i attended (pre Covid) there were a couple of members exploiting 3D printing with good success and displayed several good examples including a nice Mustang.

Would you like me to try and put you in contact with these guys with view to reducing your R & D ?

Kevin

Last edit: 3 years 8 months ago by kevinross.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

3 years 8 months ago #25720

by Brian

Replied by Brian on topic 3D Printing

There are so many things to go wrong with a 3D print, I stopped everything and reviewed the programs again. I repeated the setup tests, I reprinted the test pieces. This morning it dawned on me that I had used up so much filament that I couldn't finish the prints for the wings. Normally, the PLA filament comes on a 1Kg spool, however, light weight PLA tends to be sold in 500Gram spools. Lightweight PLA foams up when it exits the print nozzle, in fact it almost doubles in size. Hence, in theory, you get the same amount of print output from 500Grams of lightweight PLA as you would from 1Kg of standard PLA. The filament I'm using comes from Germany, and I've found that it isn't practical to use filaments from different manufacturers in a multi part assembly like a wing. Guess I'll have to be patient until sometime next week. Still, I've got the Moonglow project to get on with, and working with balsa is relaxing and very satisfying.

The following user(s) said Thank You: 4Pedalsfly, Phil Ford

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

3 years 8 months ago #25730

by Brian

Replied by Brian on topic 3D Printing

I have at last found part of the cause of the problem I've been having with printing lightweight PLA parts. The downloaded files for printing the model insisted that the various parameters set out for the printer settings must be used. Right! Finally, I did the unthinkable and read the manual. Its a very comprehensive document, details every part and the print parameters. The flow rate I was using was 100%, the manual stated 60%. The temperature I was using was 215°C, the manual stated 250°C, so the resin wasn't hot enough to foam up properly. At last, with the flow rate and temperature suitably adjusted, the parts started to print at the recommended weights.

The following user(s) said Thank You: 4Pedalsfly, Phil Ford

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

3 years 8 months ago #25731

by Brian

Replied by Brian on topic 3D Printing

Here's a wing tip being printed in Light Weight PLA from 3DLabPrint, as a buyer of their designs, I was offered a discount and free postage on two 1Kg spools of their new filament, couldn't resist the offer, the price was less for 2Kg than a certain German company was asking for two 500gram spools. The wing tip is being printed to see if it will be compatible with wing parts made with PLA from a different manufacturer. So far the results look promising, the matt and slightly fuzzy surface of the print is pretty much the same as previously printed parts from other filaments. The test will be whether the parts fit together. Exciting stuff, better go and sit down for a while.

The following user(s) said Thank You: 4Pedalsfly

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1045

- Thank you received: 415

3 years 8 months ago - 3 years 8 months ago #25738

by Brian

Replied by Brian on topic 3D Printing

Over the past few days I've discovered a hidden benefit in 3D printed models, for an assortment of reasons I haven't been able to get on with the Moonglow build, so doing a spot of 3D printing more or less made up for it. Fortunately I've just enough spare time to be able to load up the printer and leave it to weave its magic. The current project is back underway since the new spool of PLA arrived, the wing panels take around six hours to print, this means a visit to the shed first thing in the morning, followed by a second visit just after lunch. Seems almost illegal to be able to produce wing panels by simply pressing the "GO" button. Right now I'm like a little boy at Christmas, I had an email today saying that the balsa I ordered for the Moonglow is coming tomorrow. It would have been delivered sooner if I had checked rather more carefully what materials were needed.

Last edit: 3 years 8 months ago by Brian. Reason: Explanatory text added

The following user(s) said Thank You: 4Pedalsfly, Phil Ford

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.261 seconds

Latest Posts

- No posts to display.

©

2009 - 2025

WMAC PCF Design