- Posts: 3156

- Thank you received: 903

Back to Basics

- Phil Ford

-

- Offline

- Moderator

-

Less

More

14 Dec 2020 10:59 #23839

by Phil Ford

I got diverted too recently

Replied by Phil Ford on topic Back to Basics

Kevin Ross wrote: Best of luck with the Kitchen - as you know i'm no stranger to those diversions from modelling

I got diverted too recently

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

29 Jan 2021 09:36 #24122

by Brian

Replied by Brian on topic Back to Basics

I checked that the Kadet was still OK after being abandoned in favour of the delights of struggling with an IKEA kitchen build. Apart from adding a receiver and battery, there's a strip of blue tissue trim to add to the front of the fuselage, then perhaps it won't be too long before we get some freedom and a spot of decent weather to go with it. While browsing the Outerzone the other day I came across this encouraging story, thought you might like to read it.

outerzone.co.uk/viewpoint/entry.asp?ID=11

outerzone.co.uk/viewpoint/entry.asp?ID=11

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

09 Apr 2021 12:58 #24472

by Brian

Replied by Brian on topic Back to Basics

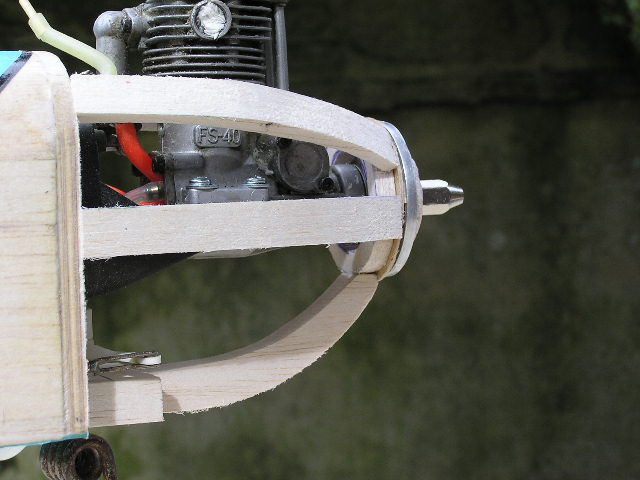

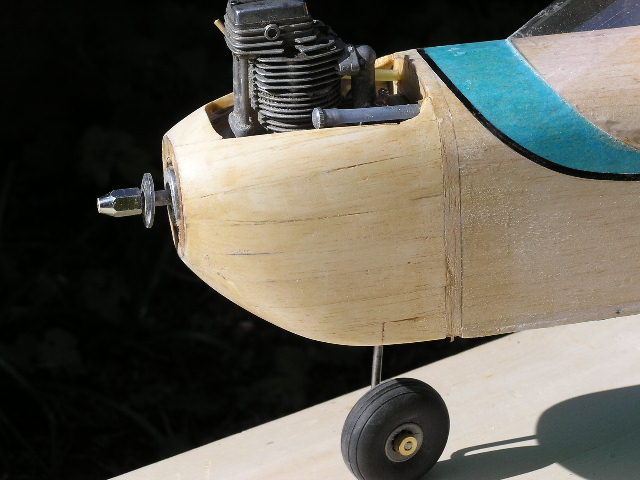

The recent warm spell got me back out into the garden working on the long overdue Kadet. The winter in a damp shed hadn't been kind to the windscreen glue, I'd left it pinned after gluing it in place, the pins had rusted and stained the glued area, and the glue hadn't set in the cold and had run into places where it shouldn't. Finally I got the screen cleaned and re-glued, this time using plated pins. The blue tissue trim on the fuselage needed to be finished, but before I could do that I had to finalised fitting the engine cowl. Once again the winter and damp had made the cowl buckle and start to delaminate. Perhaps my idea of making a cowl from tissue and PVA glue wasn't one of my better ones. When balsa was plentiful, I made cowls from block and thick sheet balsa, unfortunately I don't have any now. Rummaging in the "bits box" I came across a piece of useful looking 1/2" sheet, useful but nowhere near enough to make a cowl. Then it occurred to me that it might be possible to saw curved sections out of the sheet, and make a cowl on the same principle as making a barrel. This would be perhaps the most economic way to use the small piece of sheet balsa. Fortunately, I had a pair of rejected wing tip blocks, they yielded a couple of small but useful pieces that were 1" thick, very handy for making the underside of the cowl. The photos more show how its going better than I can describe it. No doubt there'll be a good deal of filler in the joints, but its quite encouraging to find that even the curved offcuts can be used to fill a space.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Moderator

-

Less

More

- Posts: 3156

- Thank you received: 903

10 Apr 2021 12:06 #24477

by Phil Ford

Replied by Phil Ford on topic Back to Basics

Novel way of cowling the engine Brian. I assume you will make a hatch so you can access items that inevitably will need twiddling with.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

10 Apr 2021 17:42 #24479

by Brian

Replied by Brian on topic Back to Basics

Thanks for your interest Phil. The OSFS .40 has the slow running adjustment facing up, the needle valve extension hangs out the RH side just behind the exhaust. Engine mount screws easily accessible with a Pozi screwdriver, throttle cable disconnect by upward facing M3 grub screw. The cowl is now fully assembled and glued. If its warm enough tomorrow I'll start the final shaping. The engine will be taken out so that I can fuel proof the insides of the cowl.

Please Log in or Create an account to join the conversation.

- 4Pedalsfly

-

- Offline

- Platinum Member

-

Less

More

- Posts: 800

- Thank you received: 202

10 Apr 2021 20:51 #24482

by 4Pedalsfly

Replied by 4Pedalsfly on topic Back to Basics

Good work Brian - If you get stuck for balsa again you could plan a raid on the local wind farm.

I'm about to start the rebuild of my "Rainbow " - if I cannot find a moulded cowl I may follow

your construction technique.

Colin.

I'm about to start the rebuild of my "Rainbow " - if I cannot find a moulded cowl I may follow

your construction technique.

Colin.

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

11 Apr 2021 16:51 #24487

by Brian

Replied by Brian on topic Back to Basics

Working on the Kadet's cowl was a bit of a challenge today. The bright clear and very cold morning went through some rapid changes, one being warm and sunny and one being in the middle of a sleet storm. With one eye on the weather and the other on the cowling, I carved the approximate shape with my long bladed "prop carver" from my free flight rubber years. The final contours were completed using a Perma-Grit block sander. Three coats of sanding sealer and a final rub down with 320 grit paper and the cowl is ready to be tissue covered to match the rest of the fuselage. I should have marked the cowl parts with a pencil, I used an old ball point pen, and it shows!

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

25 Apr 2021 16:46 #24577

by Brian

Replied by Brian on topic Back to Basics

Fortunately the wind on Saturday wasn't blowing in my garden so I was able to begin the final touches to the Kadet. After a lot of frustration with being completely unable to set up a Spektrum receiver with AS3X, it was plugged in to my laptop as the instructions said, but there was no way I could get the stabilising part of the thing to work. Then I swapped it for an AR 8000, bit of an overkill for the Kadet, but as it turned out, a complete waste of time. I think this receiver is a cheap copy and not a genuine item at all. Wish I'd kept the packaging now. Completely different story with a well used Spektrum AR 6210, now the Kadet has a set of working controls at last. The OSFS .40 was fired up, ran it up and set the tick over, adjusted the main needle for full throttle, set the throttle cut and checked the fail safe. Next Tuesday looks possible for a maiden, so in the meantime I'll recharge all the batteries, put some new fuel into the field container, check spare plug and props and try not to get too nervous by Tuesday.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Moderator

-

Less

More

- Posts: 3156

- Thank you received: 903

25 Apr 2021 17:15 #24578

by Phil Ford

Replied by Phil Ford on topic Back to Basics

Looking forward to seeing it fly at last - been a loooong time coming....:lol:

Please Log in or Create an account to join the conversation.

- Brian

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

26 Apr 2021 17:47 #24586

by Brian

Replied by Brian on topic Back to Basics

Moving on to the next "easy to fix" project, I've started refurbishing the Panic I was given last Summer. I did some basic structural repairs last year, just enough to make it flyable with some degree of safety. The covering is/was quite remarkable, the original appeared to be covered in translucent multi coloured pieces. Unfortunately oil had got between the pieces, and the covering was peeling off. The previous owner had coated the upper surfaces dark olive green and the underside pale grey, it looked OK from a distance, but oil had done its wicked work and around the edges the paint was semi liquid. I read up about getting oil out of balsa, didn't sound promising. After stripping all the covering from the fuselage and tail unit, I scrubbed the surfaces with alcohol and lots of kitchen paper. Heated the surfaces using a heat gun and more scrubbing with kitchen paper. After several goes, the surfaces were improved quite a bit. After lightly sanding down, I scrubbed a coat of ordinary spirit based knotting well into the balsa using a stiff brush. Next day, after another light sanding, I brushed on a coat of thinned PVA. I shall leave it for a couple of days to dry right out. In the meantime I needed to replace the elevator and rudder hinges. These were fibreglass/superglue jobs and were definitely "in for the duration". They didn't respond too well to my attempts with a balsa knife, but they yielded instantly when attacked with a thin diamond disc in a Dremel, bit smelly and best done in the open air.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.446 seconds

Latest Posts

-

-

- Valkyrie Slope Soarer

- In Activities / Glider & Slope

- by Phil Ford

- 22 Feb 2026 13:03

-

©

2009 - 2026

WMAC PCF Design