- Posts: 3170

- Thank you received: 903

CAP232 Breitling

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

10 years 4 months ago - 10 years 4 months ago #4811

by Phil Ford

Maybe your comments are always misread and have a double meaning :lol:

Things have slowed down a bit now, waiting on engine and bits-n-bobs. Still, on Sunday I rubbed down the Beast spats and repainted with 6 coats of white primer followed by 4 coats of Vauxhall Glacier White. I did not intend to do that many coats but discovered a few runs. so, force dry and rub down again. I plan on using some bright red coach-line to break up the white a bit.

Back to the wing tube Checking with digital vernier gauge it appears that the tube 25.5mm is virtually the same size as wing tube guide. I am wondering if this tube belongs to this model as the model was purchased unboxed with accessories missing. Discovered a Hangar 9 wing tube for B25 Mitchell in the garage and measuring this tube found it to be 25mm. Fits wing tubes neatly and a tiny bit of slack in fuselage. So, I have broke the bank by ordering in some 25mm plain tube from Carbonology. Hope this solves the "forcing tube" in wing issue. I'd hate to break the wing tube guides.

Checking with digital vernier gauge it appears that the tube 25.5mm is virtually the same size as wing tube guide. I am wondering if this tube belongs to this model as the model was purchased unboxed with accessories missing. Discovered a Hangar 9 wing tube for B25 Mitchell in the garage and measuring this tube found it to be 25mm. Fits wing tubes neatly and a tiny bit of slack in fuselage. So, I have broke the bank by ordering in some 25mm plain tube from Carbonology. Hope this solves the "forcing tube" in wing issue. I'd hate to break the wing tube guides.

Replied by Phil Ford on topic CAP232 Breitling

DaveBright wrote: What do you lot take me for!?

Maybe your comments are always misread and have a double meaning :lol:

Things have slowed down a bit now, waiting on engine and bits-n-bobs. Still, on Sunday I rubbed down the Beast spats and repainted with 6 coats of white primer followed by 4 coats of Vauxhall Glacier White. I did not intend to do that many coats but discovered a few runs. so, force dry and rub down again. I plan on using some bright red coach-line to break up the white a bit.

Back to the wing tube

Last edit: 10 years 4 months ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

10 years 4 months ago #4859

by Phil Ford

Replied by Phil Ford on topic CAP232 Breitling

Slow progress as some of the stuff ordered is arriving in a not ideal order. Still, managed to align and fit DLE55. Cut out cowl to suit. Then dry fit wrap-around exhaust -more cowl cutting. Will have to cut little bit more to allow for the plug cap but can't do that until I finalise where the ign module is going and can't do that because I am waiting on foam rubber.

Still, wired in the ign kill switch and programmed it in on the TX, so a flick up of the trainer switch stops engine. I have purchased a Menz wooden Prop 23 x 8 (God, 23x8 are in short supply in any material - must be popular) as a starting point but in the future probably go carbon.

I have purchased a Menz wooden Prop 23 x 8 (God, 23x8 are in short supply in any material - must be popular) as a starting point but in the future probably go carbon.

Can't glue canopy because pilot will not be here till Monday and the canopy glue may or not be here tomorrow, Saturday.

Sunday is my newest grandsons christening so RC is off for a day.

Still, wired in the ign kill switch and programmed it in on the TX, so a flick up of the trainer switch stops engine.

Can't glue canopy because pilot will not be here till Monday and the canopy glue may or not be here tomorrow, Saturday.

Sunday is my newest grandsons christening so RC is off for a day.

Please Log in or Create an account to join the conversation.

- flyingpete

-

- Offline

- Banned

-

Less

More

- Posts: 847

- Thank you received: 102

10 years 4 months ago #4861

by flyingpete

Replied by flyingpete on topic CAP232 Breitling

Looking really good Phil,but you might need to open up the cowl a bit so you get better cooling to the base of the cylinder head where it gets the hottest or use some sort of ducting, dle 55's like plenty of cooling

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

10 years 4 months ago - 10 years 4 months ago #4880

by Phil Ford

Replied by Phil Ford on topic CAP232 Breitling

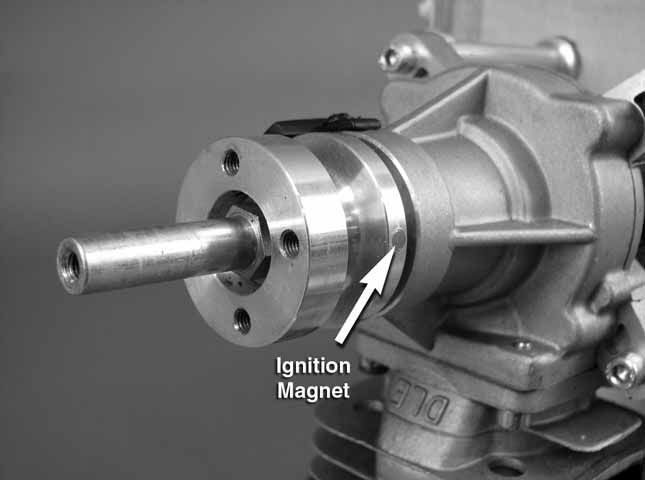

About to fit prop to drive but DLE's method has thrown me a bit!  According to the manual for the DLE55 it says, rotate crank until start of compression stroke, the magnet should be at 3 o'clock. Position prop at 1 o'clock and mark holes for drilling. See first image.

According to the manual for the DLE55 it says, rotate crank until start of compression stroke, the magnet should be at 3 o'clock. Position prop at 1 o'clock and mark holes for drilling. See first image.

So, on my DL55, with exhaust off, I rotate crank until piston just starts to pass the exhaust port (start of compression stroke). Magnet is at top on my engine. From images I would say the bolt holes would make my prop at 1.30 to 2. The latter is not an issue I would've thought. See images 2 and 3

Should I just ignore the manual and put the piston just past exhaust port then set prop to nearest 1 to 2 position?

Oh, and could I get away with not having a drill press/pillar drill?

So, on my DL55, with exhaust off, I rotate crank until piston just starts to pass the exhaust port (start of compression stroke). Magnet is at top on my engine. From images I would say the bolt holes would make my prop at 1.30 to 2. The latter is not an issue I would've thought. See images 2 and 3

Should I just ignore the manual and put the piston just past exhaust port then set prop to nearest 1 to 2 position?

Oh, and could I get away with not having a drill press/pillar drill?

Last edit: 10 years 4 months ago by Phil Ford.

Please Log in or Create an account to join the conversation.

- flyingpete

-

- Offline

- Banned

-

Less

More

- Posts: 847

- Thank you received: 102

10 years 4 months ago #4882

by flyingpete

Replied by flyingpete on topic CAP232 Breitling

You will be very lucky if you can drill.the prop without a press,I always use a press and drill the back of the prop so you end up with perfect alignment. don't worry what the manual says just go with a 2 o'clock position on compression and it will be fine

Please Log in or Create an account to join the conversation.

- Phil Ford

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

10 years 4 months ago #4883

by Phil Ford

Replied by Phil Ford on topic CAP232 Breitling

Thanks for the info Pete. I would've probably set the prop position very similar to my two stroke glows, at 2 o'clock or thereabouts if there had been no manual.  I'll have to find someone with a pillar drill. I really did not fancy drillling freehand, just a stupid thought.. :whistle:

I'll have to find someone with a pillar drill. I really did not fancy drillling freehand, just a stupid thought.. :whistle:

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.591 seconds

Latest Posts

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Brian

- 1 week 1 day ago

-

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 2 weeks 3 days ago

-

©

2009 - 2025

WMAC PCF Design