- Posts: 1179

- Thank you received: 265

Curare 60 E

- JonTappin

-

- Offline

- Platinum Member

-

Less

More

5 years 6 months ago #22085

by JonTappin

Replied by JonTappin on topic Curare 60 E

Further to Kevin's comments, I use 3 flight conditions (not sure what Futaba calls this), one for each flap position and separate the trims for each, this means that you can individually trim at each flap position, you will normally get pitch trim changes with flaps and as Kevin said unless you have the flaps travelling exactly the same distance, you can get roll changes with flap as well. This makes it easy to correct it without using mixers which normally need lots of trial and error to get right. It also means if you want more throw or less expo say with full flap, you can do this all on the same switch

The following user(s) said Thank You:

Please Log in or Create an account to join the conversation.

- kevinross

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1028

- Thank you received: 583

5 years 6 months ago - 5 years 6 months ago #22089

by kevinross

Replied by kevinross on topic Curare 60 E

Simon

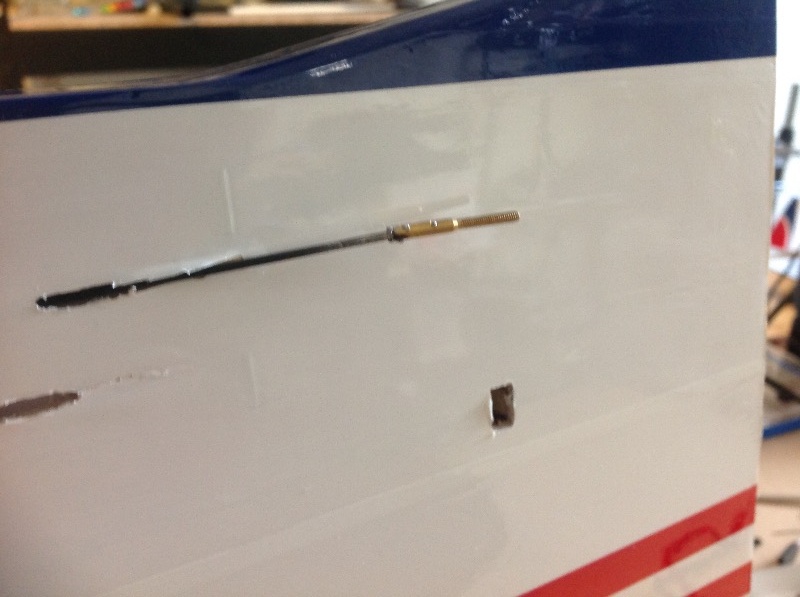

For future reference, what you should have done after trial fitting the flaps is grabbed the drive and driven ends of the torque rods with pliers and bent them to match.

However you might still be able to achieve this. Assuming the flaps are solid balsa, Try grabbing the flap with pliers and some strong ply plates to spread the load and bend / twist the torque rod to align. I would move the aft one forward. If this loosens the rod in the flap, make a small incision in the covering, dig down to the rod and wick some cyan in to make it hard !

For future reference, what you should have done after trial fitting the flaps is grabbed the drive and driven ends of the torque rods with pliers and bent them to match.

However you might still be able to achieve this. Assuming the flaps are solid balsa, Try grabbing the flap with pliers and some strong ply plates to spread the load and bend / twist the torque rod to align. I would move the aft one forward. If this loosens the rod in the flap, make a small incision in the covering, dig down to the rod and wick some cyan in to make it hard !

Last edit: 5 years 6 months ago by kevinross.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

5 years 6 months ago #22090

by Phil Ford

Replied by Phil Ford on topic Curare 60 E

FWIW I had to do that too.  I squeezed the torque area tightly with some strips of ply between my fingers and the flap. Bent the best I could get. I was maybe lucky, my epoxied glue had not loosened.

I squeezed the torque area tightly with some strips of ply between my fingers and the flap. Bent the best I could get. I was maybe lucky, my epoxied glue had not loosened.

The following user(s) said Thank You:

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

5 years 6 months ago #22094

by Phil Ford

Replied by Phil Ford on topic Curare 60 E

Simon, are you able to overcome the control rod issue?

Please Log in or Create an account to join the conversation.

-

Topic Author

Topic Author

- New Member

-

Less

More

- Thank you received: 0

5 years 6 months ago #22099

by

Replied by on topic Curare 60 E

Yes Phil, ran solder into each of the threaded brass links then solder onto the piano wire and with a hot soldering iron held against the link the wire slid into the links and made fast. Very pleased with the result!

I must say the plastic tubes that guide the closed loop wires for the rudder and the piano wires for the 2 elevators make life so much easier.

So I will now hinge the elevators and the rudder once I have fitted the respective control horns. The drilled ply piece will be glued in once the servos for rudder and elevators are finished. This will then extend the lipo battery tray.

I will go back to the torque rods for the flaps at a later date armed with the extra knowledge I now have to rectify the misaligned rods.

On we go.

I must say the plastic tubes that guide the closed loop wires for the rudder and the piano wires for the 2 elevators make life so much easier.

So I will now hinge the elevators and the rudder once I have fitted the respective control horns. The drilled ply piece will be glued in once the servos for rudder and elevators are finished. This will then extend the lipo battery tray.

I will go back to the torque rods for the flaps at a later date armed with the extra knowledge I now have to rectify the misaligned rods.

On we go.

Please Log in or Create an account to join the conversation.

- Phil Ford

-

- Offline

- Administrator

-

Less

More

- Posts: 3170

- Thank you received: 903

5 years 6 months ago - 5 years 6 months ago #22100

by Phil Ford

Replied by Phil Ford on topic Curare 60 E

Good work. Thought you had been quiet today.  When you do the elevator rods in the fuselage just check the rods still slide when they are aligned to the servo arm. If they tend to bind you may have to pack the servo up with some thin ply. I had to anyway so my rudder wires would clear the elevator servo arm (as in the full size image I sent you) Rudder? Pull pull wire or direct rod. I initially started with a direct rod but found it bound a bit in the tube on my first Curare. Hence wires.

When you do the elevator rods in the fuselage just check the rods still slide when they are aligned to the servo arm. If they tend to bind you may have to pack the servo up with some thin ply. I had to anyway so my rudder wires would clear the elevator servo arm (as in the full size image I sent you) Rudder? Pull pull wire or direct rod. I initially started with a direct rod but found it bound a bit in the tube on my first Curare. Hence wires.

Last edit: 5 years 6 months ago by Phil Ford.

Please Log in or Create an account to join the conversation.

Moderators: DaveBright

Time to create page: 0.307 seconds

Latest Posts

-

-

- Ray Ivey's Models

- In WimborneMac Members / For Sale - Exchange - Wanted

- by Brian

- 1 day 6 hours ago

-

-

-

- Various Gliders from Dave Ambrose ex W.M.A.C Membe...

- In WimborneMac Members / For Sale - Exchange - Wanted

- by 4Pedalsfly

- 1 week 3 days ago

-

©

2009 - 2025

WMAC PCF Design